Trusted by companies worldwide to streamline and drive operational excellence

Measurable waste reduction results

Our customers report significant improvements in production efficiency and cost savings after implementing Lumiform.

28%

increase in production efficiency

34%

reduction in defect rates

22%

faster quality inspections

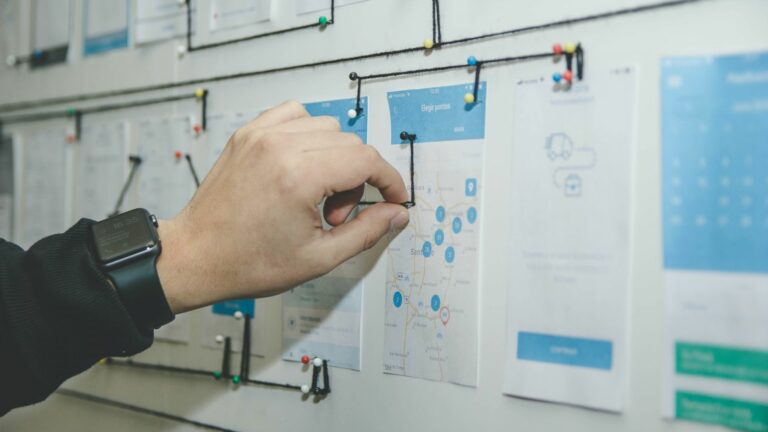

Transform your production floor with digital lean tools

Replace paper-based processes with digital tools that provide real-time visibility and actionable insights.

Reduce waste with streamlined workflows

Drive continuous improvement with data

Standardize processes across all sites

Digital lean transformation

Enhance production quality, reduce waste, and improve operational efficiency with our lean manufacturing software.

95% of companies that implement Lumiform increase their frontline teams' productivity, health, and safety

We provide you with all resources you need

Access a comprehensive suite of resources designed to optimize lean manufacturing processes, from detailed guides to real-world use cases.

Frequently asked questions

Lumiform’s software identifies the seven wastes through digital inspections, real-time issue reporting, and data analysis. It enables quick detection of defects, overproduction, and process inefficiencies, with automated actions to address problems immediately.

Yes, Lumiform enables data collection before, during, and after kaizen events. Teams can document baseline conditions, track implementation of improvements, measure results, and manage follow-up actions—all within one digital platform.

Lumiform digitizes 5S audits with photo documentation capabilities, automated scoring, and action management. Teams can conduct regular 5S assessments via mobile devices, track progress over time, and ensure accountability for maintaining workplace organization.