Trusted by companies worldwide to streamline and drive operational excellence

Prevent failures before they happen

Lumiform's predictive maintenance software helps you detect issues early and schedule repairs at the right time.

47%

reduction in unplanned downtime

36%

reduction in maintenance costs

24%

longer equipment lifespan

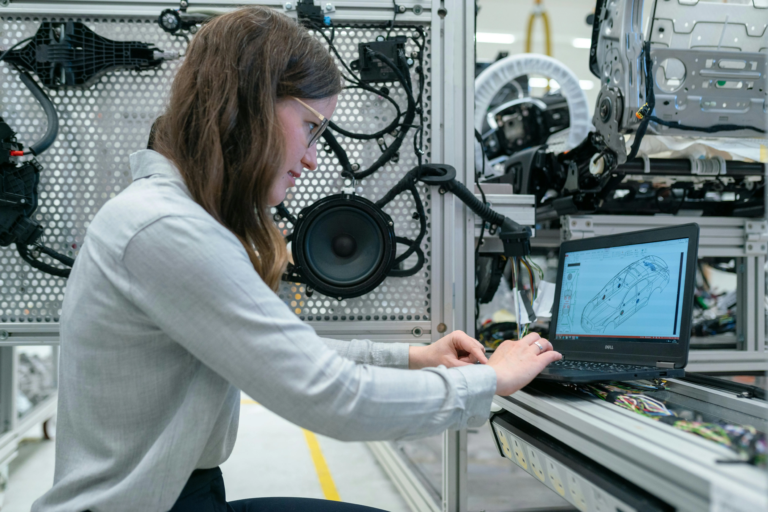

Make data-driven maintenance decisions

Turn equipment data into actionable insights that prevent costly breakdowns and extend asset life.

Prevent unexpected failures with real-time alerts

Schedule maintenance only when it’s needed

Track maintenance history and predict future needs

Get smart maintenance access

Enhance equipment reliability, reduce costly downtime, and extend asset lifespan with our predictive maintenance software.

95% of companies that implement Lumiform increase their frontline teams' productivity, health, and safety

We provide you with all resources you need

Access a comprehensive suite of resources designed to enhance predictive maintenance, from detailed guides to real-world use cases.

Frequently asked questions

Lumiform seamlessly connects with various IoT sensors through standard protocols like MQTT and REST API. The software collects and analyzes real-time data on temperature, vibration, pressure, and other critical parameters to detect potential equipment issues.

You can create customized alerts based on equipment-specific thresholds, anomaly detection, and trend analysis. Alerts can be delivered via mobile notifications, email, or within the dashboard, ensuring your team responds quickly to developing issues.

Yes, Lumiform integrates with most CMMS platforms through our API connections. This allows seamless work order generation, maintenance history sharing, and unified asset management while enhancing your system with predictive capabilities.