You can have the best product, the most efficient team, and a strong go-to-market plan, but if your suppliers fail, everything else slows down or breaks entirely. Supplier risk is not just about late deliveries or missed quality checks. It is about the ripple effects that stretch across your operations and customer trust.

That is why supplier risk mitigation matters. It is the difference between reacting to disruption and building a supply chain that can bend without breaking. When you actively assess and address risks in your supplier network, you do more than avoid problems, you create stability, increase resilience, and protect your ability to deliver, no matter what happens upstream.

Let’s look through this beginners guide to get you ready for mitigating supplier risks.

What is supplier risk mitigation?

Supplier risk mitigation is the process of protecting your business from potential problems caused by your suppliers. It involves identifying risks, such as delays, financial troubles, or compliance issues, and putting strategies in place to handle them before they disrupt your operations.

Think of it as your safety plan to keep things running smoothly, no matter what challenges arise with your suppliers.

Why is it important in modern supply chains?

If your business depends on suppliers, you already know how vital they are to your success. But recent supply chains are more complex than ever. You might be working with suppliers across different regions or industries, which means there are more opportunities for things to go wrong.

Imagine a shipment delay because a factory shuts down, or a supplier suddenly goes out of business while you’re in the middle of a key project. These kinds of disruptions can throw off your operations, hurt your reputation, and cost you money. Supplier risk mitigation helps you stay ahead of these risks, so you can avoid nasty surprises and keep your business on track.

By managing supplier risks proactively, you can keep your business running smoothly, maintain customer trust, and build stronger partnerships with your suppliers. It’s not just about avoiding problems; it’s about creating a more reliable and resilient supply chain.

The impact of supplier risks on business operations

Supplier risks can create a chain reaction that disrupts your entire business. When a supplier fails to deliver or faces challenges, it doesn’t just stay within their operations. It directly affects your ability to meet deadlines, fulfill customer orders, and maintain your reputation.

For example, if a supplier delays a shipment, your production schedule can fall behind. This might leave you unable to meet customer demands, which could result in lost revenue and strained relationships with clients. In industries where timing is critical, such as manufacturing or retail, even a minor delay can have a significant financial impact.

Supplier risks can also harm your reputation. If a supplier provides poor-quality goods or fails to meet compliance standards, your customers may see your business as unreliable. This can lead to a loss of trust and, in some cases, legal or regulatory consequences that hurt your brand image.

Operationally, supplier risks can force you to spend time and resources fixing problems. You may need to find alternative suppliers, adjust production schedules, or address quality issues, all of which can increase costs and slow down your workflows. These inefficiencies take your focus away from growing your business and achieving your goals.

In short, supplier risks can disrupt your operations, increase costs, and damage your reputation. They affect much more than just your supply chain, which is why addressing them proactively is essential to keeping your business running smoothly.

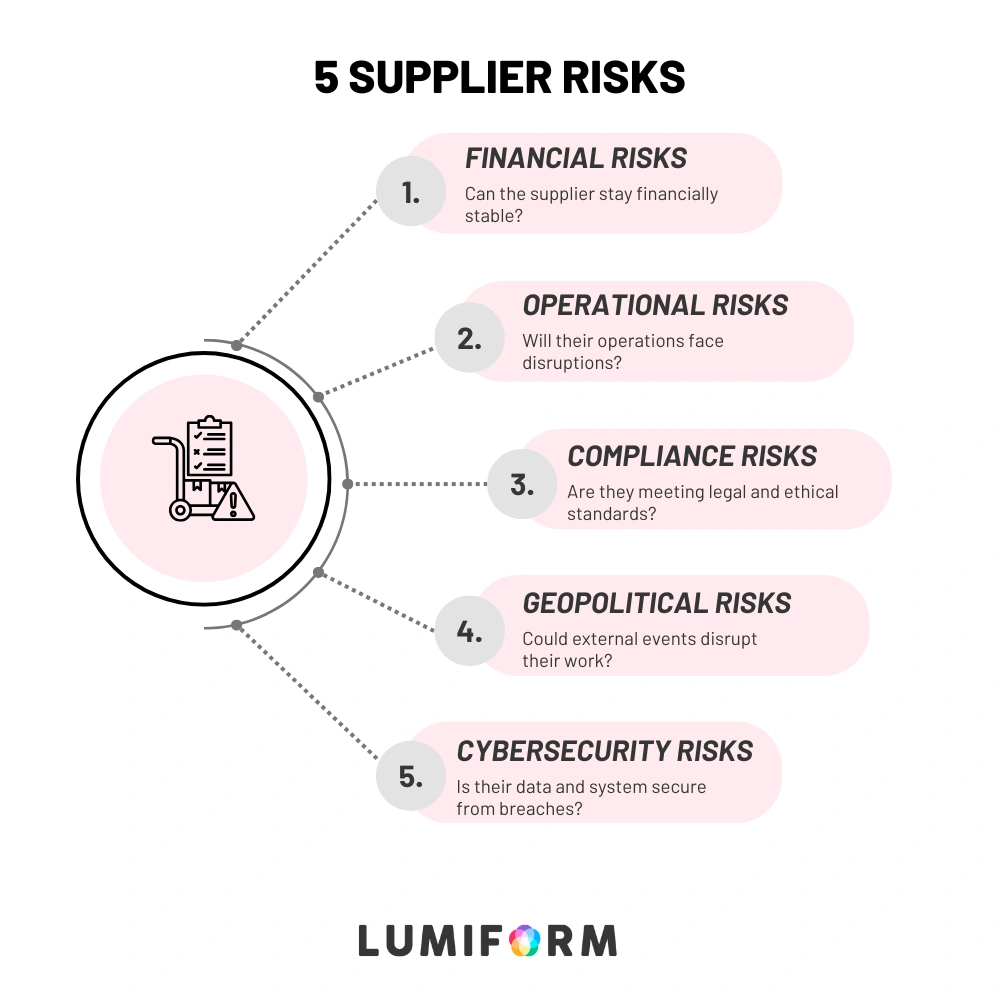

5 types of supplier risks

Understanding the different types of supplier risks is essential to protecting your business. Each type presents unique challenges, and knowing how to identify and manage them can help you prevent disruptions, save costs, and maintain smooth operations.

Below are the five key types of supplier risks and how they can impact your business.

1. Financial risks

Financial risks arise when a supplier experiences financial instability, such as cash flow problems, debt issues, or even bankruptcy. If your supplier cannot pay their own vendors or keep their operations running, they might fail to deliver the products or services you rely on.

For example, if your supplier suddenly goes bankrupt, you could be left scrambling to find a replacement, which might delay your operations or increase costs. To mitigate this risk, you can conduct regular financial health checks on your suppliers by reviewing their financial statements, credit ratings, or payment histories. Diversifying your supplier base is also a smart strategy to avoid over-reliance on a single supplier.

2. Operational risks

Operational risks occur when a supplier’s internal processes fail, leading to disruptions in their ability to deliver. This could include production delays, equipment breakdowns, staffing shortages, or quality control issues.

For instance, a supplier might face labor strikes or machinery failures that prevent them from meeting your deadlines. This can directly disrupt your production schedule and impact your ability to serve customers. To manage operational risks, you can request regular updates on your supplier’s production capacity, monitor their performance, and conduct on-site audits to ensure they have robust processes in place.

3. Compliance and regulatory risks

Compliance risks emerge when a supplier fails to meet legal, regulatory, or ethical standards. This includes issues like violating labor laws, environmental regulations, or industry-specific standards.

For example, if your supplier is found using unethical labor practices, your business could face reputational damage or even legal consequences. To mitigate this risk, you can implement a supplier code of conduct, require certifications for regulatory compliance, and perform audits to ensure they adhere to local and international laws. Transparency and accountability should be key elements of your supplier relationships.

4. Geopolitical and environmental risks

Geopolitical risks stem from political instability, trade restrictions, tariffs, or conflicts in the region where your supplier operates. Environmental risks, such as natural disasters, extreme weather, or pandemics, can also disrupt supply chains.

For example, a supplier located in a politically unstable country might face sudden shutdowns due to government policies or civil unrest. Similarly, a flood or earthquake could halt production entirely. To reduce these risks, you can diversify your suppliers geographically, build inventory buffers, and develop contingency plans for high-risk regions.

5. Cybersecurity risks

Cybersecurity risks occur when your supplier’s systems are compromised, potentially exposing your sensitive business data or disrupting operations. This could happen if a supplier is targeted by hackers or lacks adequate data protection measures.

For instance, if your supplier stores sensitive information about your orders or operations and their system is breached, it could lead to data theft or operational delays. To address this risk, you can evaluate your supplier’s cybersecurity protocols, require them to comply with your data protection policies, and establish clear guidelines for data sharing and access.

Steps to mitigate supplier risks

To effectively manage supplier risks, you need a proactive approach that combines assessment, diversification, and preparation. Here are five key steps to help you mitigate risks and maintain a resilient supply chain:

- Assess and audit suppliers regularly: Evaluate suppliers’ financial health, production capacity, and compliance with regulations to ensure they can meet your needs without disruptions. Regular audits help identify weak points before they escalate.

- Diversify your supplier base: Avoid relying too heavily on a single supplier by working with multiple vendors in different regions. This reduces the impact of issues like geopolitical instability or natural disasters.

- Monitor supplier performance with technology: Use digital tools to track delivery times, quality metrics, and compliance standards. Real-time alerts can help you address potential risks quickly and efficiently.

- Build strong relationships with suppliers: Foster open communication and collaboration with your suppliers. A strong partnership can help you resolve issues faster and ensure mutual success.

- Develop contingency plans: Prepare for disruptions by identifying backup suppliers, maintaining inventory buffers, and creating alternative workflows to keep operations running smoothly in case of emergencies.

By following these steps, you can reduce the likelihood of supplier-related disruptions and build a more reliable supply chain.

Best practices for effective supplier risk mitigation

Effective supplier risk mitigation requires a combination of proactive planning, strong relationships, and data-driven decision-making. One of the most important practices is establishing clear and open communication channels with your suppliers.

Regular communication ensures that you are aware of any potential issues on their end and can address them before they escalate. Setting clear expectations and providing detailed guidelines for quality, delivery timelines, and compliance standards helps suppliers align with your business needs.

Another best practice is collaborating with suppliers to create mutually beneficial relationships. Instead of treating suppliers as mere vendors, view them as partners in your supply chain. This collaboration can also help you identify and resolve risks more effectively.

Using data to drive decisions is another critical element of supplier risk mitigation. By tracking key performance indicators, such as delivery times, defect rates, and compliance metrics, you can monitor supplier performance and spot trends or warning signs early.

Investing in tools that centralize and analyze supplier data can help you make informed decisions and respond quickly to potential risks.

Finally, building a culture of continuous improvement is essential for staying ahead of supplier risks. Regularly review your supplier risk management strategies and adapt them to changing market conditions, supplier performance, or new technologies.

These best practices not only reduce risks but also strengthen your overall supplier relationships, improve operational efficiency, and improve your business’s ability to adapt to challenges.

How Lumiform can help with supplier risk mitigation

Lumiform is designed to simplify and strengthen your supplier risk management processes. By digitizing audits, automating workflows, and centralizing data, Lumiform helps you stay ahead of potential risks and maintain a smooth supply chain. Here’s how:

- Streamlining supplier audits with digital forms: Lumiform allows you to create custom digital forms to evaluate supplier performance, compliance, and financial health. The forms are mobile-friendly, making it easy to collect data on-site or remotely. With instant reporting, you can quickly identify risks and take corrective action.

- Automating workflows to track and resolve risks: When risks are identified, Lumiform makes it simple to assign tasks directly to team members or suppliers. Automated notifications and reminders ensure tasks are completed on time, while real-time tracking provides full visibility into progress.

- Centralizing data for actionable insights: All supplier data, audit results, and task resolutions are stored in one platform. Lumiform’s dashboards and reporting tools help you analyze trends, identify recurring issues, and make data-driven decisions to improve your supply chain.

By using Lumiform, you can streamline your processes, reduce risks, and build a more resilient and efficient supply chain.

Secure your supply chain with proactive risk mitigation

Supplier risk mitigation isn’t just about avoiding disruptions, it also creates opportunities to strengthen your business. Beyond operational benefits, a strong risk management strategy also enhances trust with your stakeholders. Customers, investors, and partners want to work with businesses that demonstrate reliability and resilience.

When you proactively manage supplier risks, you’re not just protecting your operations, you’re reinforcing your reputation as a dependable and forward-thinking organization.

The key to success lies in continuous improvement. Risk mitigation isn’t a one-time effort; it’s an ongoing process of learning, adapting, and evolving. With tools like Lumiform, you can stay ahead of the curve, ensuring that your supply chain isn’t just protected but optimized for growth. Start here!