Air compressors power countless industries, including manufacturing, construction, and even medical facilities–but they need consistent care to stay efficient and reliable. With proper air compressor maintenance, it can operate at peak capacity, while preventing issues early.

Red on for the essentials of air compressor maintenance, including best practices that you can easily add to your routine. Whether you’re managing a single unit or an entire fleet, this guide will help you maintain productivity and avoid unnecessary setbacks.

What is air compressor maintenance?

Some may be surprised to hear there are many different types of air compressors. What type you see—axial compressor, centrifugal compressor, rotary screw compressor, reciprocating air compressor, scroll compressor, oil-flooded compressor, oil-free compressor—will depend on what type of job needs doing and what industry it needs doing in.

They are all pneumatic tools that need regular inspections.Based on the air compressor inspection checklist, engineers and safety officers carry out preventive maintenance at regular intervals to ensure the reliable and optimum operation of the machines.

Air compressor preventive maintenance presents some challenges, but if it is not done regularly, the consequences can be costly. After all, anyone who ever worked a day in their life would much rather pay $20 to replace the oil rather than $4,000 for a new engine. With cars, it’s always a no-brainer. So why would it be any different for any other machine you own? To boot, air compressors are smaller with smaller repairs and smaller replacement fees, so there’s no reason why maintenance shouldn’t be done routinely.

What are the main reasons for performing routine maintenance on air compressors?

There are various types of air compressors on the market—single-stage, two-stage, piston type, oil, oilless, pressure, or without—and which one you use depends on where you are and what you’re doing, but all of them require regular maintenance to ensure efficient power distribution.

For example, air tools should be oiled regularly. Non-lubricated tools wear out many times faster and even generate less power as a result. The importance of regular maintenance of air compressors is listed below:

1. Check compressor leakage during regular maintenance

- Drop in performance

- Increased wear of the compressor due to increased running time

- Shorter service life

2. Importance of regular compressor maintenance

- Risk of rusting in the pressure vessel due to water accumulation

- Less storage volume in the pressure vessel

- Insufficient oil in the compressor can lead to increased wear or to system wide failure

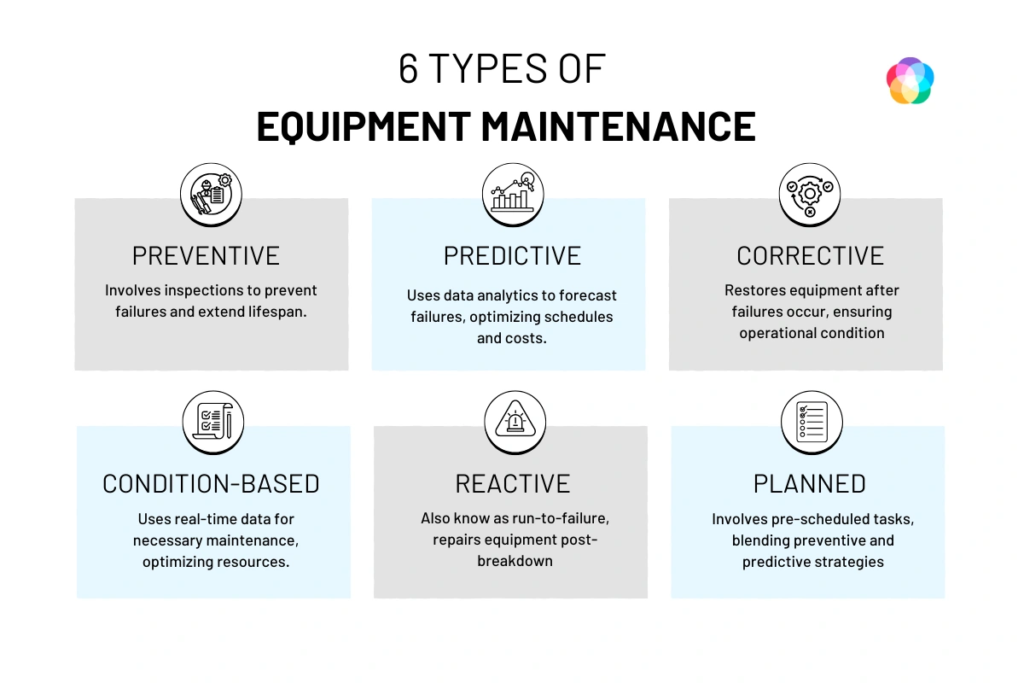

Any type of equipment should be regularly maintained to ensure it functions at all times – thus reducing the risk of equipment downtime and saving you money on costly repairs. If you want to know more about which types of equipment maintenance to consider for your air compressor maintenance, read on or check out our equipment maintenance guide.

Tips for air compressor maintenance

Follow these maintenance tips to save significant time and money in the long run. They’re also easy to implement:

Prioritize regular maintenance

First, it’s important to schedule regular maintenance for your air compressor so it keeps on running efficiently. Plan daily, weekly, and monthly checks to address critical areas like filters, tanks, and connections. You can even set reminders to stay consistent, especially if multiple team members share maintenance responsibilities. Along with this, keep a maintenance log to track completed tasks and future servicing.

Keep the compressor clean

Dust and debris are silent killers for air compressors, so make cleaning a priority. Wipe down external surfaces to prevent dirt from coming in through vents or intake areas. Then check the air filters regularly and clean or replace them as needed for proper airflow. A clogged filter forces the compressor to work harder, so this small habit makes a significant difference.

Don’t ignore the workspace itself–the area around the compressor should also be free from clutter and contaminants.

Monitor oil and lubricants

If you’re using an oil-lubricated compressor, checking oil levels regularly should be part of your routine. Before using the compressor, check if oil levels are within the recommended range with the sight glass or dipstick. Low oil levels can lead to increased friction and damage, while overfilled systems may cause leaks.

Replace the oil at intervals based on the manual or sooner if it appears dark or contaminated. The type of lubricant matters, too—always use the one recommended by the manufacturer.

Drain moisture frequently

Moisture accumulation in the air tank is a common issue that can lead to rust and reduced performance. Make it a habit to drain the tank often–even every day–especially if your compressor runs in a humid environment.

Most tanks have a valve at the bottom for easy drainage. Open the valve slowly to release water while the compressor is turned off and depressurized. You can also use an automatic drain valve to make the process easier.

Inspect leaks often

Air leaks are efficiency killers, wasting energy and forcing the compressor to work harder to maintain pressure. Conduct regular leak inspections by listening for hissing sounds or applying soapy water to hoses, fittings, and connections. If bubbles appear, it means there’s a leak that needs immediate attention.

For a more systematic approach, incorporate a leak inspection into your maintenance schedule. Use tools like ultrasonic leak detectors for hard-to-spot issues.

Be proactive with parts replacement

It’s natural for machines to develop worn-out parts, especially for filters, belts, and seals. Don’t wait for them to fail before replacing them. Instead, inspect these parts for signs of wear and replace them as needed to keep the system running reliably. You can also stock spare parts so you can stay prepared when you need to do replacements.

Ensure proper ventilation

Compressors generate significant heat when in use, and without proper airflow, they might overheat, which can damage internal components. Put your compressor in a well-ventilated area, away from walls or obstructions that might block cooling vents. There should be enough space around it for heat to dissipate effectively. If there’s naturally high temperature or poor airflow, consider adding external cooling systems like fans or air conditioning.

Schedule professional servicing

Routine maintenance covers most day-to-day care, but you’ll still need professional servicing for a thorough inspection. Schedule annual or semi-annual checkups with a certified technician who can identify issues that might not be obvious during regular maintenance. They can perform advanced diagnostics, check internal components, and recalibrate the system if needed so it operates at peak efficiency.

Professional servicing is also required for staying compliant with industry standards and safety regulations, especially if your compressor is used in high-stakes environments..

What are the advantages of compressor maintenance?

Below are the 3 main reasons for predictive maintenance on compressors:

1. Maintaining efficiency

As expected, air compressors should operate at optimum levels within their running time. Routine compressor maintenance by engineers helps identify problems early on that can lead to inefficiencies, such as low compressor capacity or long-running time caused by possible leaks in safety or suction valves.

2. Ensuring safety

Depending on the type of compressor, an uncontrolled operation can lead to an accumulation of condensation which, in turn, causes internal corrosion and weakens the system, and can even lead to unexpected explosions. Blocked components or lack of ventilation can cause air compressors to overheat.

You can explore these pre-made air compressor inspection checklists to proactively identify problems and keep your equipment safe to use.

3. Ensuring compliance

International standards such as ISO 45001 for health and safety at work, by law, require proof of equipment maintenance. Regular compressor maintenance and digital documentation enables companies to comply with international safety standards.

A digital solution to maintaining air compressors

An air compressor maintenance checklist contributes to the efficient and safe operation of plants. However, the proper documentation of maintenance results is sometimes neglected or not done regularly. With Lumiform, you’ll find free digital maintenance templates. Plus, the mobile and powerful inspection application will help you overcome these and other challenges:

- Individual digital forms: The flexible form builder makes it possible to create new individual checklists at any time and adapt them again and again.

- Scheduling and notifications: The Lumiform app ensures that schedules are kept. All employees receive notifications about upcoming procedures and due dates. Managers automatically receive notifications when assignments are overdue and problems arise.

- Time-defined work steps: Keep an eye on your schedule and use the information to identify opportunities to increase your efficiency.

- Faster identification and resolution of problems: The data you collect from your inspections are collected in the app. You can then access all data and view your performance reports broken down by time, location, and department. This helps you quickly identify the root cause of a problem, so you can fix them as quickly as possible.

- Track inspections in facilities over time: Monitor your team’s inspection performance and identify opportunities to improve the process and organize your operations.

- Integrations: Connect Lumiform’s software to enterprise software systems.

- Time-defined targets: Keep an eye on what’s happening to identify insight to increase your efficiency.