Every bite you serve matters. In the food industry, a single mistake can cost you your business and harm your customers’ health. Globally, foodborne illnesses lead to $110 billion in losses each year, making food safety guidelines crucial for maintaining brand trust and business success.

Whether you’re managing a restaurant, a food industry professional, or cooking at home, these compliance protocols are designed with you in mind.

In today’s digitally connected world, where consumers are more informed and regulations are tougher, even slight errors can have serious impacts. That’s why this guide is your ultimate resource, packed with ready-to-implement food safety guidelines, actionable insights, and expert tips to empower you.

With these tools, you can ensure every dish you serve is mouth-watering and safe. So, dive in and transform your approach to food safety today!

What are food safety guidelines?

Food safety guidelines are a set of principles and practices designed to ensure the food you produce, handle, or serve is safe for consumption. They cover every stage of the food supply chain—from sourcing and storage to preparation and delivery, helping you prevent contamination, protect public health, and meet regulatory requirements.

These guidelines are your blueprint for minimizing risks, avoiding costly mistakes, and maintaining consumer trust.

At the core of food safety are regulatory standards such as the Food and Drug Administration (FDA) in the U.S., and the European Food Safety Authority (EFSA) regulations in Europe.

Also, there are HACCP (Hazard Analysis and Critical Control Points) frameworks, and ISO 22000 standards, which provide structured systems to manage food safety.

However, depending on your region and industry, you may also need to adhere to local laws. Requirements may even include obtaining licenses and approval from the food administration agencies. Staying compliant isn’t optional. It’s your ticket to staying in business and avoiding fines, lawsuits, or closures.

The scope of food safety guidelines

Food safety guidelines are vital across a wide spectrum of industries and professional roles. They are not limited to restaurants or small food establishments but extend to large-scale operations, logistics, and specialized roles within the food industry. Here are two scenarios:

- For businesses: Food production companies rely on food safety protocols to maintain consistency and quality, from raw materials to packaged products. Similarly, logistics and supply chain managers play a critical role in preventing contamination during storage and transport.

- For professionals: Food safety officers and inspectors act as compliance gatekeepers. Meanwhile, quality assurance (QA) teams oversee safety protocols, ensuring they are consistently applied across operations. Their attention to detail minimizes risks and improves operational efficiency.

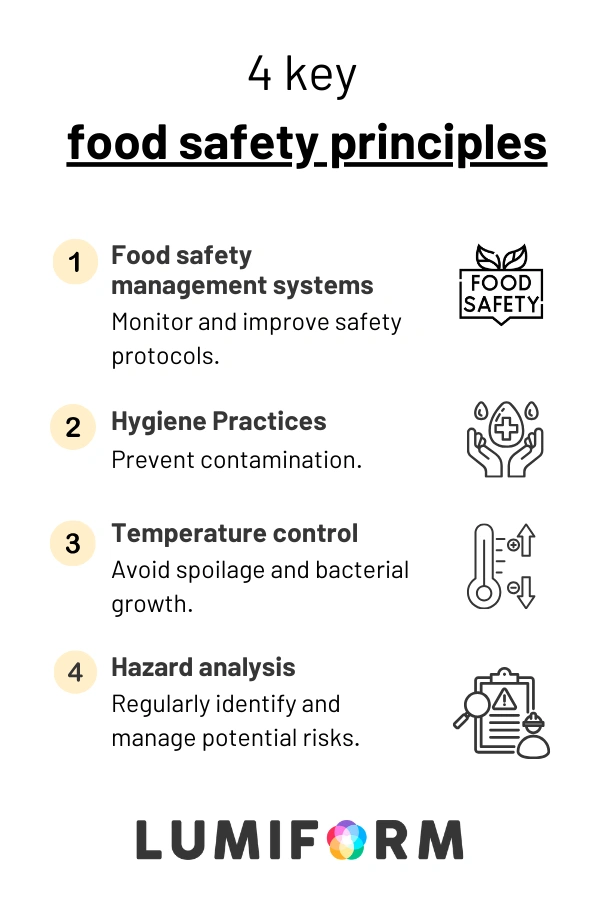

4 key food safety principles

Adhering to key food safety principles is essential for businesses aiming to protect consumers and maintain compliance with regulatory standards. Let’s explore 4 essential principles:

- Food safety management systems (FSMS): A robust FSMS is the backbone of effective food safety practices. It provides a structured framework to monitor, evaluate, and improve safety protocols across your operations. By implementing FSMS, you can streamline audits, reduce risks, and maintain high standards.

- Hygiene and sanitation practices: Hygiene and sanitation are non-negotiable. To minimize contamination risks, enforce strict personal hygiene practices and establish cleaning schedules tailored to your facility’s needs.

- Temperature and storage control: Store raw materials and finished products at the appropriate temperatures [you can use this temperature log checklist] to prevent spoilage and bacterial growth. For example, cold foods should be kept at or below 5°C (41°F), while hot foods should be kept at or above 60°C (140°F) to prevent bacterial growth.

- Hazard analysis and risk management: Identifying potential hazards in your food handling processes is key to risk management. Conduct regular hazard analysis to pinpoint biological, chemical, or physical risks that could compromise product safety. Develop preventative measures and establish critical control points to monitor and address these risks effectively.

By focusing on these components and actively managing each area, you’ll create a robust food safety system that protects your customers, builds trust, and ensures the success of your business.

Step to implement standard food safety guidelines in your business

Ensuring food safety in your business operations goes beyond following regulations. You and your team should adopt a proactive safety culture that integrates safety into every aspect of your organization. Here is a step-by-step method for implementing a system to protect your product:

Step 1. Create a culture of food safety

Establishing a strong food safety culture lays the foundation for consistent practices and accountability.

- Foster safety awareness: Conduct a hygiene audit and reassess your situation. Employees must wash their hands thoroughly with soap and warm water for at least 20 seconds before handling food.

- Enforce health policies: Immediately send home employees showing signs of illness, and allow their return only after clearance by a healthcare professional.

- Mandate proper attire: Ensure all personnel wear clean uniforms, hairnets, gloves, and necessary PPE such as face masks or aprons.

- Communicate regularly: Highlight the importance of food safety during team meetings and reinforce positive practices.

Step 2. Develop standard operating procedures (SOPs)

SOPs provide clear guidance for handling food safely at every stage of the process.

- Map out processes: Document each step in the food cycle, from procurement to delivery.

- Address specific risks: Include measures to prevent contamination, equipment misuse, or temperature fluctuations.

- Keep it current: Regularly update procedures to reflect new regulations or operational changes.

- Distribute widely: Ensure all staff have access to these procedures and understand their responsibilities.

Step 3. Train employees to recognize and mitigate risks

Effective training ensures your team understands and applies food safety practices consistently.

- Introduce training sessions: Conduct hands-on training sessions to identify and mitigate risks such as cross-contamination or improper storage.

- Create a process: Provide checklists and guides for routine tasks to ensure clarity and adherence.

- Regularly review and update knowledge base: Schedule regular refresher courses to keep the team updated on new safety standards and technologies.

Step 4. Promote and reward a culture of maintenance

A clean and well-maintained facility is the backbone of food safety.

- Establish cleaning schedules: Cover all factory areas, including machinery, surfaces, floors, and storage areas.

- Implement pest control measures: Conduct regular inspections, seal entry points, and dispose of waste properly.

- Calibrate and maintain equipment: Ensure tools like thermometers, scales, and packaging machines are serviced according to manufacturer guidelines.

Step 5. Improve temperature control and monitoring systems

Precise temperature management ensures product safety throughout the food cycle.

- Install monitoring systems: Use digital temperature logger templates to track storage, cooking, and processing areas.

- Monitor transportation conditions: Ensure that products remain within safe temperature ranges during transit.

- Set alerts: Use automated systems to notify the team of any temperature deviations.

Step 6. Ensure your records are traceable

Accurate documentation strengthens compliance and enhances traceability.

- Maintain comprehensive logs: Record cleaning activities, temperature monitoring data, and employee training certifications.

- Implement traceability systems: Track raw materials and finished products from origin to destination.

- Facilitate audits: Ensure records are accessible and up-to-date for inspections and compliance checks.

Step 7. Develop emergency procedures

Be prepared to address incidents swiftly and effectively to minimize harm.

- Create an emergency protocol: Develop a clear protocol for addressing contamination or allergen exposure incidents.

- Encourage delegation and collaboration: Assign roles for quick resolution and ensure first-aid kits are accessible.

- Keep an emergency contact list: Maintain an updated list of emergency contacts, including regulatory authorities.

- Run drills: Conduct drills to ensure staff are familiar with procedures and can respond confidently.

Conducting food safety inspections with Lumiform

Are you worried about ensuring safety, quality, and compliance while delivering delicious meals? With Lumiform, you can tackle these demands seamlessly. Build a custom HACCP food safety plan in minutes using our food safety templates powered by key guidelines, or even start from scratch. Streamline your audits and inspections, accessing all records in one place, no matter the size.

Organize tasks, assign them to your team, and review inspections effortlessly. Use our drag-and-drop builder to create a tailored HACCP framework, incorporating text, checkboxes, and photos. Ensure your food safety processes are thorough and efficient with Lumiform’s comprehensive tools.

Click here to pick a template.

Implementing food safety guidelines: Challenges and solutions

Ensuring food safety is crucial for businesses of all sizes, yet many face significant challenges in maintaining robust safety standards. Here are common obstacles and practical solutions to help businesses overcome them:

- Resource constraints for small businesses:

- Challenge: Limited financial resources, small teams, and lack of advanced technologies.

- Solution: Focus on critical areas like temperature control and hygiene. Use affordable tools such as digital temperature logs and low-cost sanitation products.

- Supply chain risks:

- Challenge: Risks include delayed deliveries, inconsistent quality, and contamination during transport.

- Solution: Build strong relationships with reliable suppliers and regularly audit the supply chain for vulnerabilities like inadequate packaging. To achieve this, improve your supplier selection process.

- Consistency across global operations:

- Challenge: Ensuring uniform food safety standards across various locations with differing regulations and practices.

- Solution: Standardize core safety protocols and ensure regular training and communication to align all staff on food safety practices.

By addressing these challenges with targeted solutions, businesses can enhance their food safety systems, ensuring the well-being of their customers and the success of their operations.

Run your first food safety inspection now!

Fantastic work! You’ve mastered the essentials of food safety guidelines—now let’s put that knowledge to work. Kick things off by reviewing your current practices, setting ambitious safety goals, and spotting areas for improvement. Think small steps, big impact!

Dive into our free food safety templates from Lumiform and get your team cooking up success!

Click here to start now!