A permit-to-work system is critical for ensuring safety and compliance, especially in industries like manufacturing, construction, or energy. If your work involves complex safety protocols, then you’ll need to have a structured system in place for handling work permits.

With proper permit to work, you can manage hazardous tasks properly, and everyone on-site understands their responsibilities and the risks involved. In this guide, we’ll explore the key components and documentation of a permit-to-work system so you can protect your workforce.

What is permit to work?

A permit-to-work (PTW) is a system that’s designed to keep people safe when performing potentially dangerous tasks in high-risk environments, like construction sites and oil and gas facilities. It’s essentially a written agreement between management and workers. The goal is to identify specific risks, implement safety protocols, and take necessary precautions before the work begins.

Some examples of tasks requiring permit to work include:

- Welding near flammable chemicals

- Handling or disturbing asbestos material

- Tasks at elevated levels, which require fall protection measures

- Working with live electrical circuits

For a comprehensive permit-to-work system, you’ll have to evaluate risks, define safe work procedures, provide necessary personal protective equipment, and have an emergency response plan. While you’ll need several documents for this, including safety checklists and training records, the primary document will be the work permit form.

Using a work permit form

Work permit forms are used to regulate high-risk tasks. Acquiring one of these permits means conducting risk assessments, creating safety protocols, and communicating risks effectively.

A manager usually issues safe work permit forms to allow a group of people to perform a specific task under strict controls at a specific time and place. Authorized workers must follow the conditions of their permit.

No matter what task is being performed, safe work permits share an aim and general procedure. They typically work by:

- Determining high-risk areas

- Determining hazardous tasks

- Identifying the scope of work and associated risks

- Assigning specific personnel to authorize high-risk work

- Ensuring that workers and staff receive proper training

- Ensuring on and off-site employees know their roles each day

When a job has the potential to cause injury or death, a safe work permit form is necessary. You don’t have to start from scratch, though–here are some work permit form templates that you can readily download and customize based on your needs.

Common work permit forms

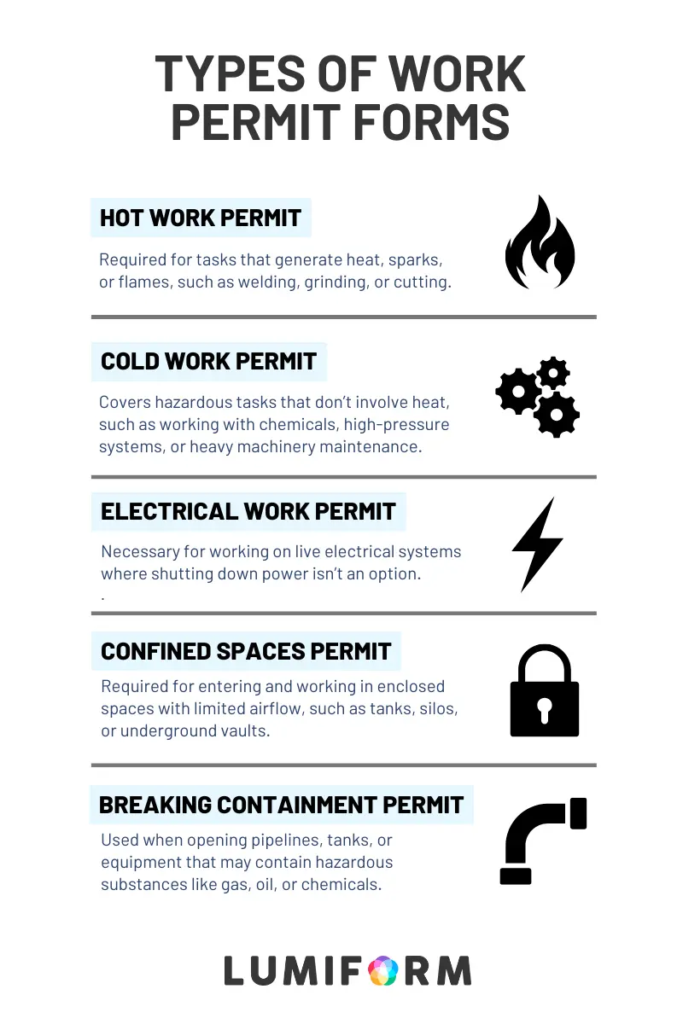

There are 5 types of tasks that most commonly require permits:

Hot work permit

Hot work permits are necessary when working with extreme heat or ignition sources that may contain flammable vapor. It’s also a requirement in jobs where workers are exposed to fire safety risks, potential explosions, or toxic fumes.

Hot work permits are most common in cutting or welding jobs that use portable gas. Separate work permits are needed for each area where hot work is done.

Cold work permit

A cold work permit, also called a general work permit, is issued when performing a hazardous task that isn’t covered by other safe work permit forms. However, the definition of cold work can vary from site to site.

Activities that generally require cold work permits include:

- Cleaning that uses chemicals or solvents

- Handling toxic chemicals or substances

- Using resins during blade repair

- Painting

- Assembling and dismantling scaffolds

- Use of heavy lifting equipment, such as cranes

- Any type of hazardous activity

Energized electrical work permit

The energized electrical work permit is used for jobs that involve pipework or disconnecting equipment that contains hazardous substances.

Electrical work permits require qualified personnel to assess the task to determine whether it can be done safely. In their assessment, they need to provide:

- A step-by-step procedure for performing the task from beginning to end

- A description of the safety precaution that will be taken

- Results of their shock and arc flash hazard analyses

- Shock protection boundaries

- Personal protective equipment for workers to wear during the job

- Protocols in place to restrict unauthorized people from the work area

Confined spaces permit

A confined spaces permit is a safe work permit that describes precautions taken to eliminate exposure to hazardous fumes or oxygen-depleted areas before people are allowed to work in a confined space. These forms should indicate that work areas are free from dangerous fumes or gases.

Aside from that, it should also indicate the possibility of fumes from residues, oxygen depletion due to oxidation, or the presence of airborne contaminants from nearby sources.

The permit needs to specify which safety precautions were taken to protect enclosed spaces from possible hazards. It should indicate any personal protective equipment that your workers will use while performing the task.

Breaking containment permit

A breaking containment permit is used in the oil & gas industry, where fatal accidents are unfortunately common. The permit ensures that operations taking places in hazardous areas are properly planned.

Essential components of a work permit

Work permits protect workers when they perform high-risk activities. However, permits only increase safety if the procedures outlined are followed and documented.

In order for a permit-to-work system to have an impact, it needs to include:

Permission to carry out tasks

Work permits specify the person who will authorize a job, including the necessary safety and health protocols. A manager should sign it before work begins so they can verify that all requirements are met.

A plan for every aspect of the work

Plans, precautions, and emergency requirements should be included in every safety work permit form. High-risk activity should never start without the appropriate risk assessment in place.

Documentation of safety precautions

There should be a detailed description of every safety check-up performed before, during, and after the work is done. Thorough safety inspections will reveal issues to correct.

Risk assessments and method statements

Safe work permit forms need to be supported by detailed risk assessments that control the risks posed by the work. This risk assessment should cover people involved in the job, the step-by-step process, individual worker permission, and the checks carried out. You also benefit from a safe work method statement, which includes the details of work processes.

Steps of the permit to work process

With key documents in place, the permit-to-work process has several major steps that require clear communication between workers, supervisors, and safety officers:

1. Permit request

The process begins when a task that requires special safety measures is identified. The person responsible for the task—such as a supervisor or manager—submits a request for a work permit. They’ll use this to describe the task, potential hazards, and safety measures to address those risks.

2. Risk assessment

Before the permit is issued, a detailed risk assessment is conducted. This assessment identifies all potential dangers associated with the task, such as exposure to hazardous materials or working in confined spaces. You’ll have to attach supporting documents, like as method statements, safety protocols, and job safety analyses (JSA), to provide a comprehensive safety plan.

3. Review and authorization

An authorized person–usually a safety officer or site manager–reviews the permit and its supporting documents. They’ll check if all safety controls are in place and confirm that the task can be performed safely. The permit will only get issued after thorough review and approval.

4. Briefing and work execution

Once the permit is authorized, a pre-work briefing is conducted with the team responsible for the task so they understand the risks and their individual responsibilities. Workers confirm they have the required training, certifications, and personal protective equipment (PPE) to carry out the job safely.

With the permit in hand, the authorized workers begin the task. Throughout the work, they must strictly follow the safety protocols outlined in the permit, with the supervisor monitoring the team.

5. Permit extension or suspension

If the task takes longer than expected or if there are major changes–such as hazards–the permit may be extended or temporarily suspended. For example, if work is paused due to weather, the permit is updated before the task can resume. This flexibility ensures that the permit system remains responsive to real-time changes in the work environment.

7. Closure

Once the task is completed, a post-work inspection is conducted. This ensures that the site is left in a safe condition and that no residual hazards remain. Any equipment used during the task is decommissioned, and the work area is checked for safety.

The permit is then signed off by the supervisor or safety officer, officially closing it. If there were any incidents or safety concerns during the task, they are documented as part of the closure process for future reference.

Streamline permit to work processes with automation software

A work permit form is too important to trust to paper, which is easy to misplace or damage. You also need work documents that can be easily shared among your team. That’s why creating and managing said documents is easier with workflow automation software like Lumiform.

With a combination of desktop software and a mobile app, Lumiform makes it easy to draw up, store, and present safe work permit forms. Simply download a premade safe work template or make your own with the custom checklist creator. You can instantly approve these forms by sending them to relevant personnel. In addition to making permit creation easier, Lumiform:

- Lets you report any issues you find during a risk assessment instantly right from the app

- Allows you to complete required tasks up to 4x faster

- Standardizes the way you perform inspections and approve high-risk tasks, since everyone is using the same checklist

- Enables you to assign corrective actions to your workers and address risks in real-time

- Provides automatic and regular analytics you can use to uncover areas where errors are more common and improve safety measures in the future

- Stores all the data you collect with it in the cloud, so it’s secure and can be accessed at any time