Poka Yoke is a Japanese term that translates to “mistake-proofing” or “error-proofing.“ It refers to any mechanism in a process that helps an operator avoid (yokeru) mistakes (poka). The concept was developed in the 1960s by Shigeo Shingo, a prominent figure in the Toyota Production System, as part of efforts to improve manufacturing processes and enhance quality control.

The origins of Poka Yoke can be traced back to the need for efficiency and quality in manufacturing. In the post-World War II era, Japan faced significant challenges in rebuilding its economy and industrial base. Companies like Toyota sought innovative solutions to improve production methods and reduce waste.

Shingo’s approach emphasized the importance of designing processes that inherently prevent errors rather than relying solely on inspection after the fact. When describing the system in his book Zero Quality Control, Shingo outlined three basic principles behind Poka Yoke:

- The best tool to prevent product defects is one that isolates the source of the problem.

- Mistakes are inevitable, defects in product are not

- A mistake must be detected before it becomes a defect

The term “Poka Yoke” was introduced as a way to create systems that would either prevent errors from occurring or make them immediately obvious when they did occur. This proactive approach not only minimized defects but also fostered a culture of continuous improvement within organizations.

Poka Yoke plays a vital role in quality management and error prevention for several reasons:

- Customer satisfaction: Quality products lead to higher customer satisfaction and loyalty. Poka Yoke contributes to this by ensuring that products meet specifications consistently, resulting in fewer returns due to a reduction in defective products and improved brand reputation as companies known for high-quality products gain a competitive advantage.

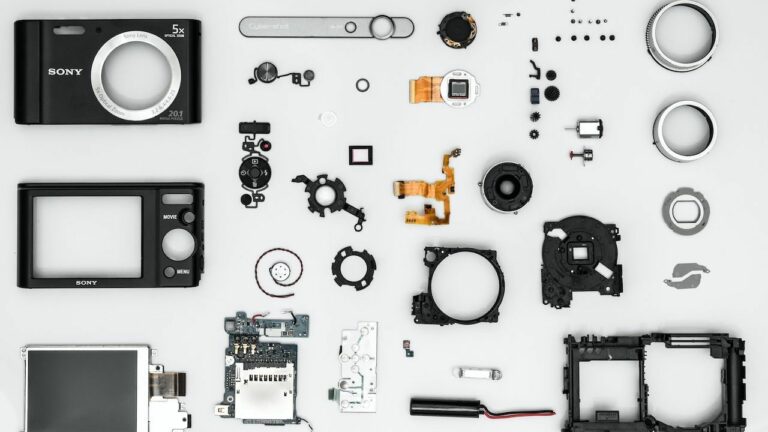

- Error reduction: By incorporating Poka Yoke mechanisms into processes, organizations can significantly reduce the likelihood of human errors. These mechanisms take various forms, such as tools or fixtures that ensure correct assembly of parts (e.g., jigs that allow assembly in only one orientation), color-coded components or labels that guide operators in performing tasks correctly, and alarms or sounds that alert workers when an error is about to occur.

- Process improvement: Poka Yoke encourages organizations to analyze their processes critically and identify potential failure points. This analysis leads to streamlined operations by eliminating unnecessary steps and focusing on error prevention, making processes more efficient. Additionally, equip workers with tools and knowledge to perform their tasks accurately, reducing the need for extensive training on error correction.

- Cost savings: Mistakes in manufacturing can lead to significant costs associated with rework, scrap, and customer dissatisfaction. By implementing Poka Yoke systems, organizations can minimize material waste caused by defects and lower inspection costs, as fewer errors occurring diminishes the need for extensive inspection processes.

The concept of Poka Yoke is simple: When there are no errors during production, the result will be a high-quality product that does not need revising. Consequently, it lowers costs at the same time and increases customer satisfaction. In addition, not only is the concept simple, the tools and/or devices must be simple.

This is a similar approach to Lean Manufacturing; the Six Sigma approach, and the 5S System which all advocate the enormous potential of keeping your organizational system concise and simple.

Understanding the principles of Poka Yoke

Poka Yoke, or mistake-proofing, is a concept aimed at designing processes to prevent errors in manufacturing and other operations. The fundamental idea is to create systems that either eliminate the possibility of human error or make errors immediately detectable.

Designing processes to prevent errors involves several strategies:

- Forcing functions: These are design changes that compel users to follow correct procedures, such as fixtures that only allow parts to be assembled in a specific orientation.

- Error detection: Implementing mechanisms that identify mistakes after they occur but before they cause further issues, such as sensors that detect missing components.

- Fail-safe designs: Creating processes that ensure failures do not lead to catastrophic outcomes, allowing for safe operation even when errors occur.

- Environmental design: Modifying the work environment to reduce the likelihood of errors, such as improving lighting or organizing tools for better accessibility

By embedding these principles into manufacturing processes, organizations can enhance quality, reduce costs associated with defects, and improve overall efficiency.

Real-life examples of brands that use Poka Yoke

Poka Yoke principles are effectively applied in various everyday products, enhancing safety and usability. Here are detailed examples involving specific brands:

1. Cars

Toyota incorporates numerous Poka Yoke features in its vehicles to enhance safety. For instance, their cars include seat belt alerts that remind passengers to buckle up before driving. Additionally, Toyota vehicles utilize automatic braking systems that engage when sensors detect potential collisions, significantly reducing the risk of accidents.

2. ATMs

There are banking financial institutions that have implemented several Poka Yoke mechanisms in their ATMs. These machines sound alarms if users leave their cards in the slot, prompting immediate retrieval. Furthermore, ATMs ensure users do not lose money by automatically retracting cash if they don’t collect it within a set time.

3. Hotel keycards

Hilton hotels utilize energy-saving systems with key cards. When guests insert their key card into a power switch upon entering their room, it activates electrical appliances. Removing the card when leaving cuts off power, preventing energy waste. This system enhances security by allowing hotels to deactivate lost cards quickly.

4. Electric plugs

Manufacturers of electric plugs exemplify Poka Yoke principles through polarized designs that allow insertion only one way, preventing incorrect connections that could lead to electrical faults. Additionally, the grounding pin on these plugs ensures safety by connecting first, reducing the risk of electric shock.

These examples illustrate how Poka Yoke principles can be present in everyday products by various brands to enhance safety, efficiency, and user experience.

Methods of Poka Yoke mechanisms

Poka Yoke mechanisms are designed to prevent errors by making it impossible for mistakes to occur or by highlighting errors immediately so they can be corrected. There are several types of Poka Yoke mechanisms, each serving a unique function in error prevention.

The first type is the contact method, which involves physical contact to detect anomalies. This method relies on sensors or other physical devices to identify when an error has occurred. For example, in manufacturing, a contact sensor detects if a component is missing or improperly placed, preventing the assembly from moving forward until resolving the issue.

The second type is the fixed-value method, which ensures that a specific number of actions or items are present before the process can continue. This method proves particularly useful in situations requiring a precise count, such as packaging processes where each box must include a set number of items. By verifying the count, the fixed-value method helps prevent errors related to quantity discrepancies.

Lastly, the motion-step method focuses on the sequence of operations. It ensures performance of steps in the correct order and prevents omission of any steps. This method can be useful in complex assembly lines where the sequence of tasks is critical to the final product’s quality. By controlling the flow of operations, the motion-step method helps maintain consistency and reduces the likelihood of errors due to skipped or out-of-order steps.

However, production experts Richard Chase and Douglas Stewart define a few more types of Poka Yoke in their work Mistake-Proofing: Designing Errors Out. These four new types can be adapted to other markets easily, and they are:

- Physical method: This is a mechanism that prevent errors in products and operations by identifying physical anomalies, similar to those examined in contact methods.

- Sequential method: It used to ensure that a specific production order or sequence is followed. Making sure workers understand the importance of following each step in sequence is key to quality manufacturing.

- Grouping method: This involves tools or components pre-arranged in sets, so that it’s easy to tell when a component has been forgotten

- Information method: It is a mechanism that immediately inform workers of production status, which update consistently. Nowadays, this is often done using digital reporting tools.

Before you implement Poka Yoke techniques, be aware that the system involves different types of inspections with different purposes. There are three inspection techniques, and they are:

- Inspections conducted at the source which aim to detect errors where they occur, before they cause defects.

- 100% defect inspection, which involves using sensitive mechanisms, such as a limit switch or warning buzzers, to mistake-proof the process.

- Automatic inspection which use electronic devices that detect errors in the machine.

Any well-designed Poka Yoke inspection will use all three of these inspection types. Poka Yoke processes also perform one of two functions. They are:

- Control function: Mechanisms and devices serving to control the production process warn you of potential failures before they happen. If there was already an error, control mechanisms will halt the production process until the worker has corrected the error. If the error has not happened yet, production will halt until conditions are correct.

- Warning function: Devices that fulfill the warning function of Poka Yoke will simply alert workers to the presence of errors. This is done by using flashing lights, buzzers, bells, or other noticeable signals. Since these devices only let you know an error has occurred, it is up to individual workers to identify and address the problem.

Benefits of Poka Yoke

Poka Yoke is a popular system because it has numerous benefits, even beyond ensuring you end up with high-quality products. This is why it is so widely used by companies today. As mentioned, it reduces the likelihood of errors in the manufacturing process. This leads to an increase in production quality and incorporates feedback obtained through observation of past errors.

Poka Yoke also saves you time and money, because you will not have to deal with repairing already-made products, or worse, recalling them entirely. By using such a defect management system, you can make fast and effective corrections if something does go wrong.

Mistake proofing improves employee conditions by reducing the need for discipline from supervisors. Avoiding human error also prevents workers from losing motivation every time they make a mistake. Poka Yoke makes work easier and creates a better working environment due to the increased safety of powerful automatic inspections.

Finally, improving your manufacturing process and producing products with fewer defects improves the consumer experience. The principle of reducing human error also applies to final products, which makes goods and services more convenient to use.

Best practices for Poka Yoke implementation

Implementing Poka Yoke effectively requires a strategic approach that aligns with the specific needs and processes of an organization. Here are some best practices to consider when integrating it into your operations:

- Thoroughly analyze processes: Begin by conducting a detailed analysis of your current processes to identify areas where errors frequently occur. Understanding the root causes of these errors is essential for designing effective Poka Yoke solutions that address the specific challenges faced by your organization.

- Involve cross-functional teams: Engage teams from various departments, including engineering, quality assurance, and operations, in the design and implementation of poka mechanisms. This collaborative approach ensures that diverse perspectives are considered, leading to more robust and comprehensive solutions.

- Focus on simplicity and clarity: Design Poka Yoke mechanisms that are simple and easy to understand. Employees are more likely to adopt and use a solution correctly when it is straightforward. Clear instructions and intuitive designs help minimize the risk of errors.

- Integrate with existing systems: Ensure that the mechanisms are seamlessly integrated into existing workflows and systems. This integration minimizes disruption and encourages smooth adoption by employees, enhancing the overall effectiveness of the Poka Yoke solutions.

- Continuously monitor and improve: Implement a system for monitoring the effectiveness of the mechanisms and be ready to make adjustments as necessary. Continuous improvement is key to maintaining the relevance and efficiency of error-prevention strategies in response to changing processes and technologies.

- Provide training and support: Educate employees about the purpose and function of Poka Yoke mechanisms. Providing comprehensive training and ongoing support helps ensure that employees understand how to use these tools effectively and appreciate their role in enhancing quality and safety.

Implementing Poka Yoke in various industries

Even if it’s not apparent at first, Poka Yoke examples are all around us. The subtlety of their presence is an indication of just how smooth it is to implement. You can find Poka Yoke examples in both businesses and daily life. Here’s how it’s useful in the manufacturing, retail, and construction industries:

Manufacturing

In the manufacturing industry, Poka Yoke is essential for preventing defects and ensuring product quality. In automotive assembly lines, alignment pins and fixtures commonly ensure that parts can only be present in the correct orientation.

This prevents assembly errors and guarantees that components fit together precisely. Additionally, sensors detect missing or improperly installed components by verifying that all screws are present and tightened to the correct torque before a product advances to the next production stage.

Retail

In the retail sector, Poka Yoke helps improve customer service and operational efficiency. Checkout systems, for example, use barcode scanners to automatically apply the correct price to each item, reducing the likelihood of human error during manual price entry. This ensures accurate pricing for customers.

Furthermore, automated inventory tracking systems help prevent stock discrepancies by alerting staff when stock levels fall below a certain threshold or when there is a mismatch between recorded and actual inventory, maintaining accurate stock levels and reducing the risk of stockouts or overstocking.

Construction

In the construction industry, workers use Poka Yoke to enhance safety and ensure quality in building processes. For instance, they use color-coded components and connectors to ensure that only the correct parts are in specific locations, preventing assembly errors and structural issues.

Additionally, they apply Poka Yoke techniques to safety equipment, such as harnesses and scaffolding, designing mechanisms to prevent improper usage. For example, scaffolding systems might include built-in levels to ensure proper alignment and stability before use, reducing the risk of accidents.

By implementing Poka Yoke across these industries, organizations can significantly reduce errors, enhance safety, and improve overall efficiency and quality control.

Poka Yoke examples in daily life

Just like production processes are mistake-proof thanks to application of Poka Yoke systems, final products use these principles so that consumers will not misuse or break their purchase. Poka Yoke examples in everyday product use include:

- USB devices which only fit your computer one way, preventing you from accidentally breaking your flash drive or harming the port.

- The Microsoft Word prompt which asks if you want to save your document before closing the program, in case you accidentally close it without meaning to.

- When you exceed the weight limit in an elevator, it sounds an alarm and stops until you remove enough weight.

- When you use your computer and it starts to overheat, it will warn you of the problem, Island eventually shut down if you do nothing.

- Machines like washing machines and microwaves won’t start until you close and lock the door.

Enhance your processes with Lumiform

Introducing Poka Yoke to your business is easier than ever now with the variety of digital solutions available, like cloud-based software and apps. With a digital solution like Lumiform, you can easily create checklists and templates that your employees can use to audit their production work and record errors that they observe. You can easily receive and process your information because the system automatically stores all data, allowing you to refer back to it when it’s time to further optimize your processes.

Whether it’s ensuring precision in manufacturing, accuracy in retail transactions, or safety in construction, Poka Yoke serves as a vital tool for achieving these goals. With features such as automated task assignments, real-time data analytics, and comprehensive reporting, Lumiform helps you optimize your operations and maintain high standards of quality and compliance.

You can start now with our 14 day free trial and drive your organization towards greater efficiency and excellence.