Keeping your air compressor running smoothly involves having a comprehensive maintenance routine. An air compressor maintenance checklist helps you stay on top of inspections, catch small issues before they get worse, and keep your equipment performing at its best.

With the checklist templates below, you can stay organized and track tasks like oil changes, filter checks, and pressure gauge readings with ease. Explore them to simplify your maintenance process and go through each step efficiently.

Essential air compressor maintenance checklists

These checklists are all easily customizable, and you can save them as PDFs or as digital forms to fit your workflow:

Air compressor maintenance checklist

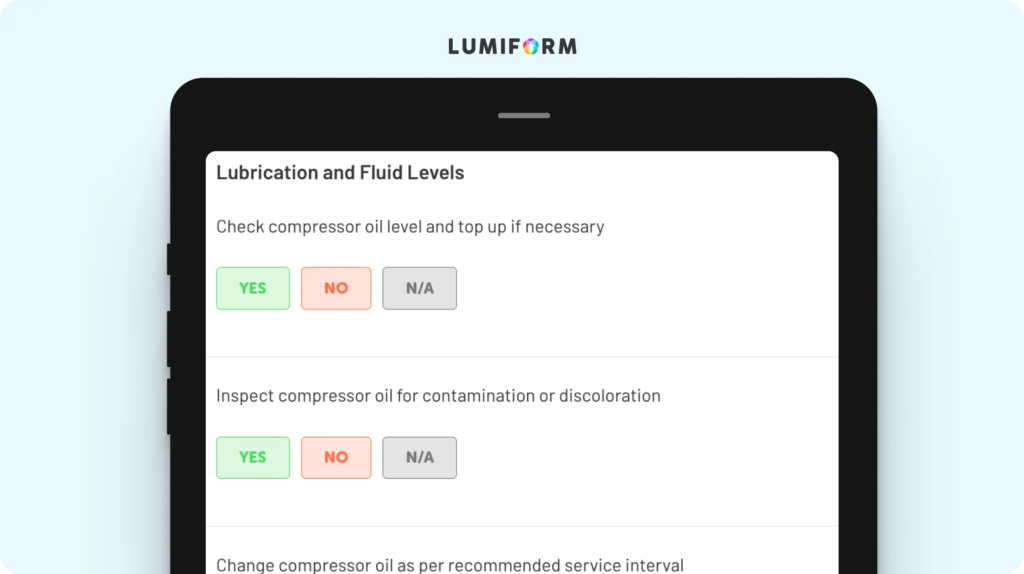

Keeping your air compressor in top condition starts with a solid maintenance routine. This template is your guide to organizing and tracking essential tasks like checking for air leaks, inspecting filters, and monitoring oil levels. Designed to help streamline routine upkeep, it ensures that no critical steps are overlooked. You can easily tweak it to suit your equipment’s specific needs, such as adding custom inspection points or adjusting intervals for recurring tasks. By tailoring this checklist, you not only enhance the efficiency of your maintenance.Air compressor preventive maintenance checklist

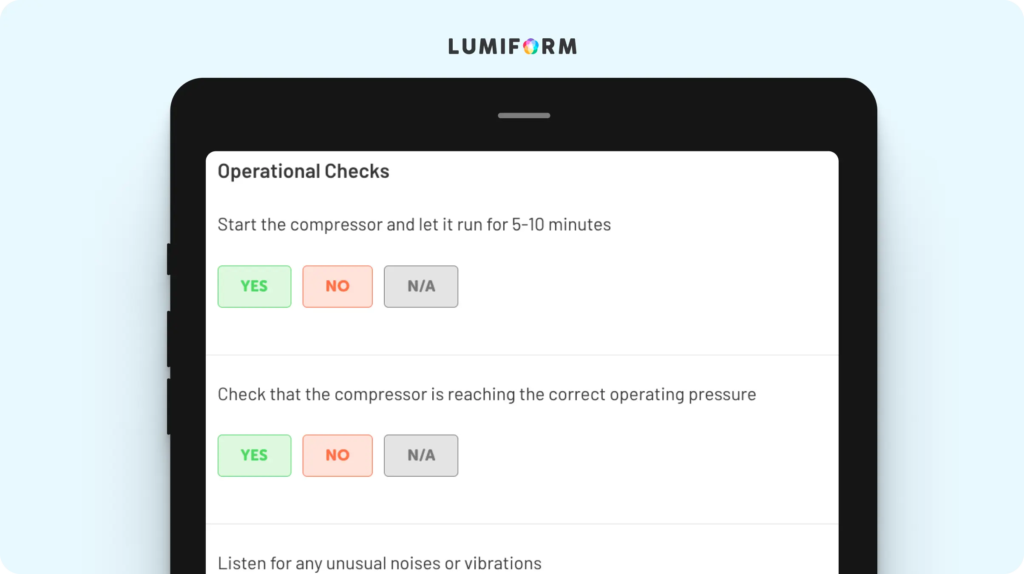

Preventive maintenance is your first line of defense against unexpected downtime. Use this checklist to schedule proactive care, from belt tension adjustments to lubrication checks. This way, every component receives the attention it needs before issues arise. Customize it by including manufacturer-recommended tasks or site-specific requirements, allowing you to add it seamlessly into your workflow. A well-structured checklist like this can save time, reduce repair costs, and keep operations running smoothly.Ingersoll Rand air compressor maintenance checklist

Tailored to the specific demands of Ingersoll Rand air compressors, this template simplifies routine care for these high-performance machines. It includes essential tasks like inspecting cooling systems, testing safety valves, and cleaning filters. You can adjust the checklist to match the model or application you’re working with, whether it’s in a workshop or industrial setting. By personalizing the tasks to fit your compressor’s unique specifications, you ensure consistent performance and avoid unnecessary wear.Atlas Copco Air Compressor Preventive Maintenance Checklist

Atlas Copco compressors are known for their reliability, and this preventive maintenance checklist is designed to keep them that way. With reminders for routine checks like pressure gauge calibration and oil change schedules, it helps you stay ahead of potential problems. Feel free to tailor the checklist to fit your specific model and operating environment, leading to smoother operations and higher equipment efficiency.Air compressor daily maintenance checklist

Daily maintenance might seem small, but it’s the foundation of keeping your air compressor in excellent shape. This checklist covers quick yet crucial tasks like draining moisture from tanks, inspecting hoses, and ensuring pressure levels are optimal. You can adjust it to reflect the demands of your daily operations, such as adding more checks for heavily used equipment. By integrating it into your routine, you can maintain consistent performance and catch potential issues before they escalate.

How to create an air compressor maintenance checklist in Lumiform

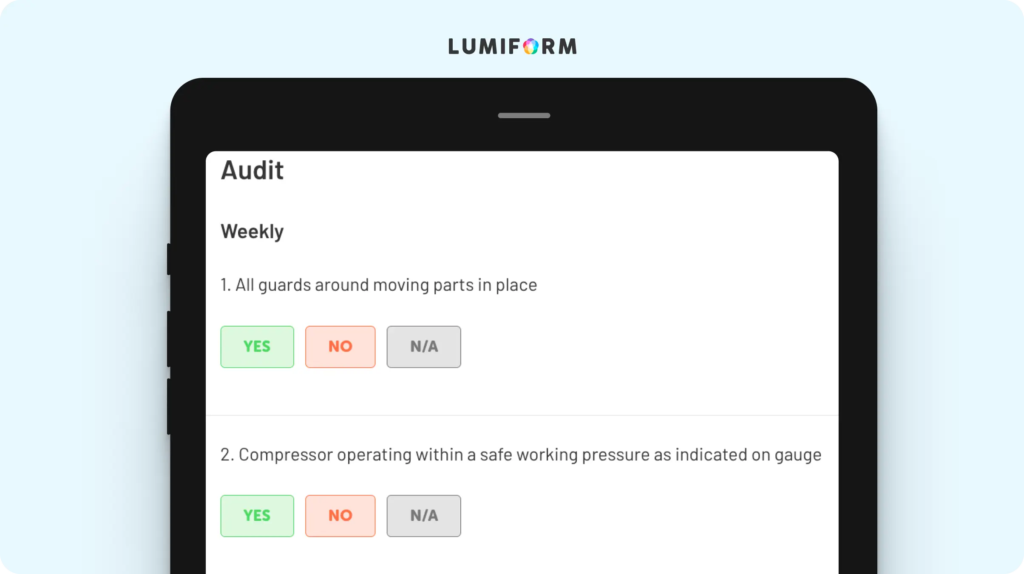

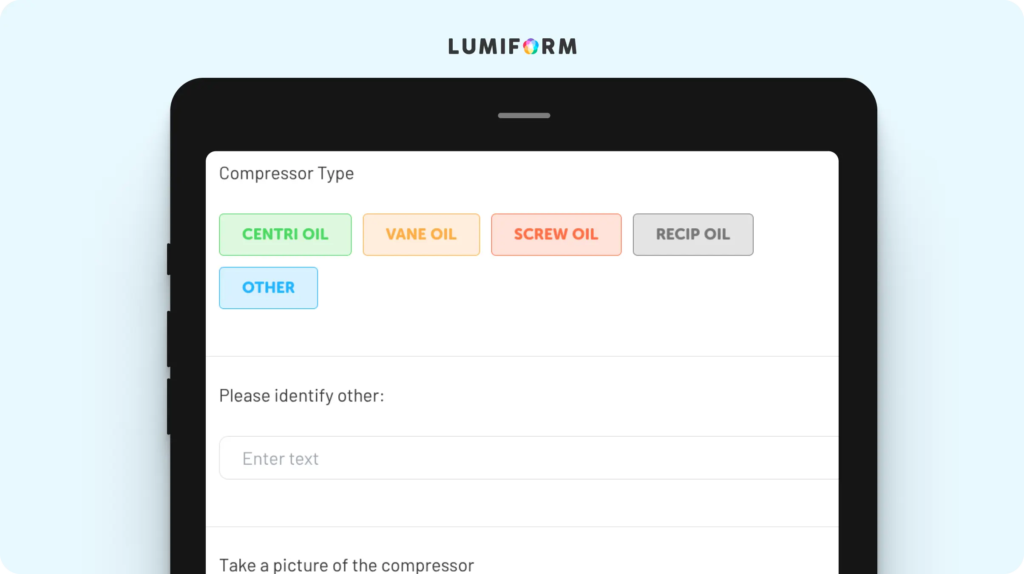

Building an effective air compressor maintenance checklist in Lumiform is quick and intuitive, thanks to the drag-and-drop form builder. You can structure your template to include all essential tasks—like oil level checks or filter inspections—and tailor it to your equipment’s unique needs. To document wear and tear, add fields to upload photos directly during inspections for detailed records every time.

The mobile app makes the checklist easy for your team to use in the field. Your technicians can access and fill out forms on-site, even offline, ensuring consistency no matter where they are. If issues arise, they can flag them instantly and assign follow-up tasks to the right person, keeping everyone up-to-date.

After the checklist is completed, Lumiform lets you analyze the data and generate detailed reports to spot trends and improve processes. Whether you’re preventing downtime or fine-tuning your maintenance plan, these tools help you ensure smooth operations with less hassle.