Blasting is one of the most hazardous operations in mining and construction. After all, just one missed step can lead to major accidents, delays, or regulatory issues. This is why seasoned professionals rely on a consistent blasting safety checklist to double-check each phase of the process, from site preparation to post-blast inspection.

A thorough blasting safety checklist keeps everyone aligned on responsibilities, ensures compliance with safety standards, and helps you catch potential hazards before they escalate. With the checklist templates below, you can run safer, more efficient operations with less stress while maintaining a clear audit trail.

Top blasting safety checklists

Document and streamline your blasting operations from start to finish using these templates:

Blasting safety checklist

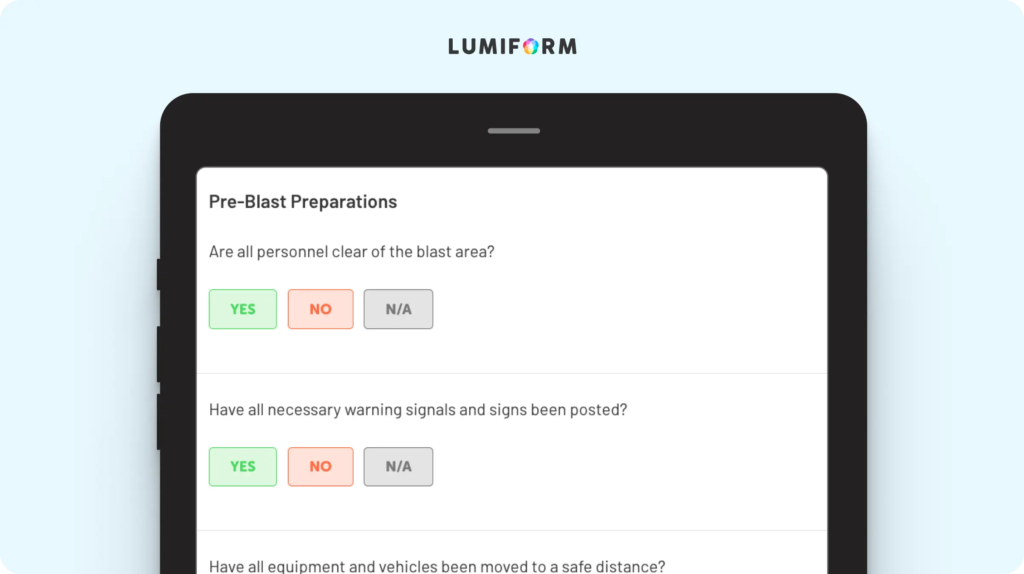

Keeping your blasting operation safe and compliant starts with a clear process, and this checklist helps you lock in just that. Designed for surface and underground blasting jobs, it guides you through key safety measures before, during, and after each blast. You can document hazard assessments, verify personnel positions, check equipment conditions, and confirm communication signals all in one place. Built-in fields for digital signatures, photo evidence, and timestamped entries make it easier to maintain accountability across your crew. To tailor the checklist to your site’s needs, add location-specific hazards or task-specific protocols to the form.Sandblasting safety checklist

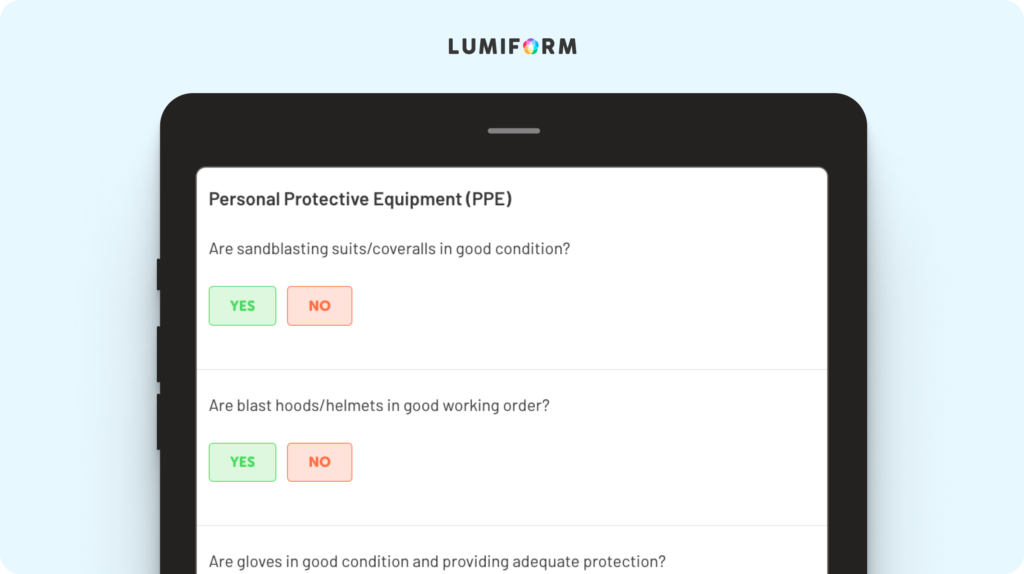

Sandblasting comes with its own set of risks, such as flying particles, pressurized equipment, and exposure to harmful dust. This template aids you in staying on top of it all. It offers a step-by-step tool to confirm PPE compliance, equipment readiness, and workspace ventilation before work begins. It also prompts you to assess weather conditions, inspect hoses and nozzles, and document crew assignments. The checklist is pre-structured but easy to adjust—just plug in your own SOPs or add fields for project-specific hazards and reporting needs. It’s especially useful for facilities or contractors juggling multiple jobsites and teams, giving you consistent oversight no matter where work is happening.Abrasive blasting safety checklist

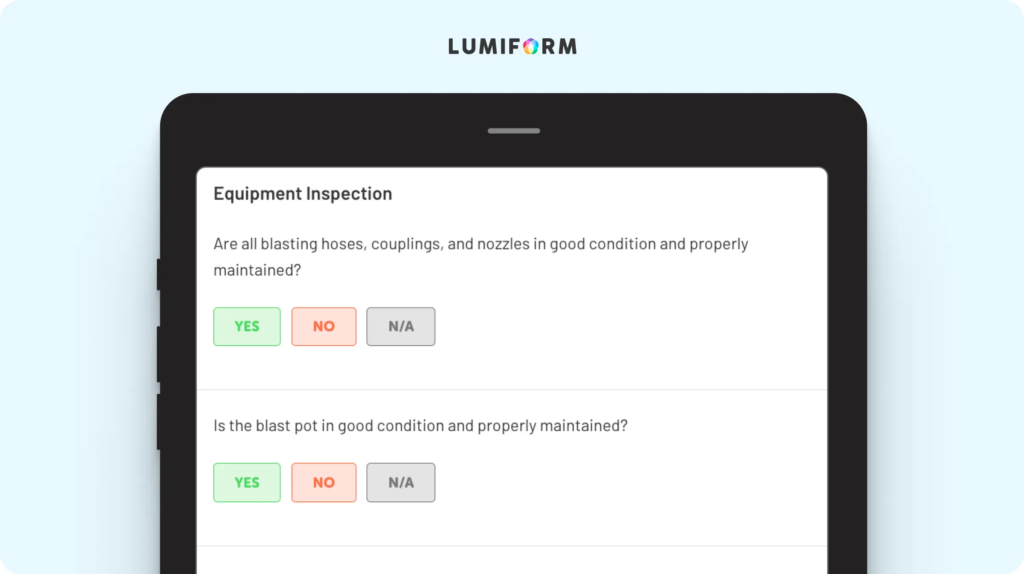

When you’re dealing with abrasive blasting—whether it’s with glass beads, steel grit, or aluminum oxide—precision and protection go hand-in-hand. This checklist helps ensure that both the operator and the environment are safeguarded at every stage. You can log PPE inspections, verify containment setup, monitor air quality controls, and check you have correctly stored and labeled blast media. There’s space to include equipment maintenance checks, crew briefings, and emergency procedures. Want to make it your own? Add material-specific safety steps or link to MSDS documentation within the form to streamline your workflow.

How to create a blasting safety checklist in Lumiform

To build a blasting safety checklist in Lumiform, start by choosing one of the customizable templates above or creating your own directly using the AI form builder. You can tweak the checklist to mirror your exact workflow, whether that includes pre-blast briefings, equipment checks, or post-blast inspections. This reduce oversight and keep everyone aligned.

Add photo fields to capture visual proof of barricades, signage, or site conditions for better documentation and faster incident reviews. Multiple-choice and number fields also make it quick to verify blast specs, while digital signatures confirm accountability.

Use the mobile app so your crew can access and complete the checklist on-site, even in remote locations. If something’s off—like damaged cables or unclear signal plans—you can flag it and assign a task on the spot, ensuring you keep track of key details. Once the job’s done, the app lets you generate a detailed report to streamline compliance and audit preparation.