Compressed air systems are a critical part of many industries, but they can quickly become a hidden source of inefficiency and rising costs if not properly maintained. A compressed air audit checklist helps you systematically evaluate your system, identify leaks, and optimize performance.

Without a clear checklist, it’s easy to miss issues like pressure imbalances, undetected leaks, or outdated components that drive up energy consumption. These oversights can lead to higher operational costs, unexpected downtime, and also compliance risks.

Using a compressed air audit checklist allows you to simplify maintenance, improve system performance, and reduce unnecessary expenses. It’s a practical tool for ensuring your operations run smoothly while meeting energy efficiency goals and maintaining workplace safety.

Compressed air audit checklists

Ensure the efficiency, safety, and reliability of your compressed air systems with these comprehensive audit checklists, designed to help you identify issues, optimize performance, and maintain compliance.

Compressed air audit checklist

This checklist helps you evaluate the efficiency and performance of your compressed air system by guiding you through key areas like leak detection, pressure monitoring, and energy usage. It includes features such as detailed inspection points for equipment and system components, ensuring a thorough review. You can easily tailor the checklist to focus on specific machinery or processes in your facility, making it a versatile tool for identifying inefficiencies and reducing operational costs.Compressed air dryer maintenance checklist

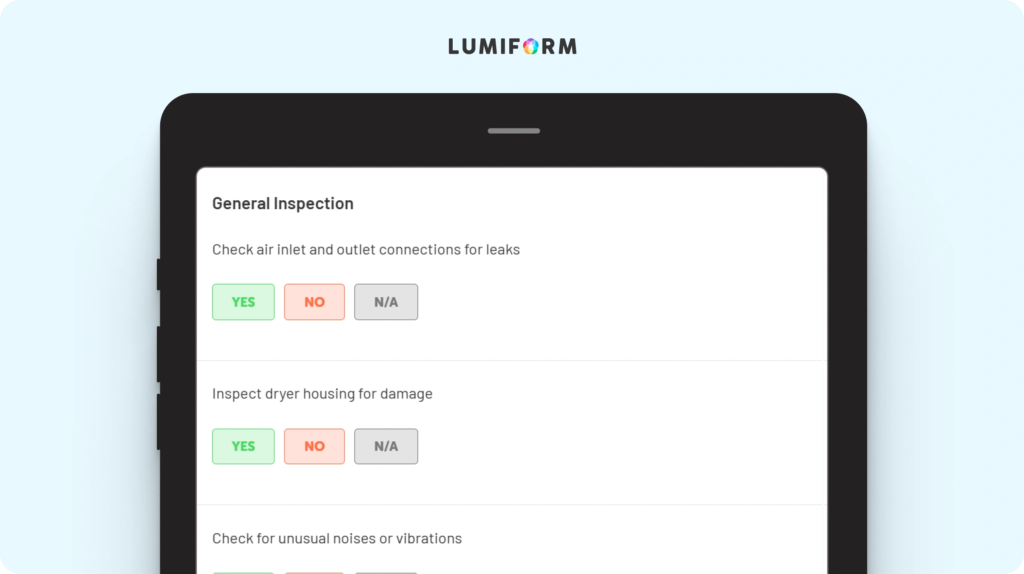

Designed to streamline maintenance routines, this checklist ensures your compressed air dryer operates at peak performance. It covers essential tasks like filter inspections, desiccant replacement, and checking moisture levels, helping you prevent costly downtime. By customizing it to your specific dryer model or maintenance schedule, you can ensure consistent upkeep and extend the lifespan of your equipment, all while maintaining optimal air quality for your operations.Compressed air testing SOP template

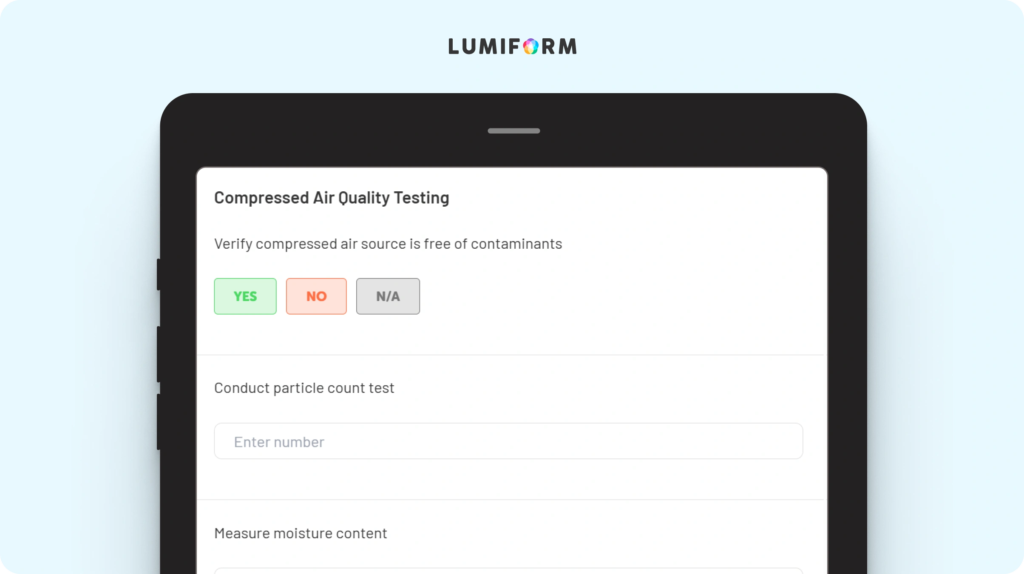

This template provides a step-by-step framework for conducting compressed air quality tests, ensuring compliance with industry standards and operational safety. It highlights critical testing parameters such as particle count, moisture levels, and oil content, helping you maintain system integrity. You can adapt the template to include specific testing intervals or additional quality benchmarks relevant to your operations, ensuring it aligns perfectly with your workflow and regulatory requirements.Compressed air risk assessment template

This template helps you identify and mitigate risks associated with compressed air systems, covering areas like equipment failure, safety hazards, and energy inefficiencies. It features a structured approach to assess potential risks and prioritize corrective actions, ensuring a safer and more efficient workplace. Customize it by adding facility-specific risks or adjusting severity levels to create a tailored risk management plan that meets your operational needs.

How to create a compressed air audit checklist in Lumiform

Creating a compressed air audit checklist in Lumiform is simple and ensures your team can conduct audits efficiently while achieving consistent results. Start by using the drag-and-drop form builder to include key elements like multiple-choice questions for leak detection, number fields to record pressure readings, and also photo uploads to document system conditions.

To make the checklist as easy to use as possible for your team, add logic-based questions that guide users through the process based on their inputs. For example, if a pressure drop is detected, the checklist can automatically prompt additional inspection steps. This also ensures thorough audits without overwhelming your team with unnecessary tasks.

Once created, assign roles to team members directly within the app, ensuring accountability and a smooth workflow. By including QR codes on equipment, your team can quickly access the checklist on-site, saving time and improving accuracy.

After the audit, Lumiform’s analytics tools help you track trends and identify inefficiencies, enabling you to take proactive steps to improve system performance.

With Lumiform, you can create a tailored checklist that simplifies audits, reduces errors, and improves the overall efficiency of your compressed air system.