Ensuring proper hand safety is essential in industries where workers are exposed to risks like sharp tools, heavy machinery, or hazardous materials. A hand safety checklist helps you create a structured approach to identifying hazards and assessing risks, while implementing protective measures.

Without a clear checklist, it’s easy to overlook critical steps like inspecting personal protective equipment (PPE), ensuring proper glove selection, or training employees on safe handling techniques. This can also lead to preventable accidents, downtime, and compliance issues.

A detailed checklist helps you maintain thorough documentation, improve workplace safety, and meet regulatory standards.

Using a hand safety checklist streamlines your safety audits, ensures compliance, and keeps your team protected. It’s a vital tool for fostering a safer and more efficient work environment.

Customizable hand safety checklists

Ensure optimal hand safety in the workplace with these essential checklists designed to help you identify hazards, enforce protective measures, and maintain compliance with safety standards:

Hand safety checklist

This checklist helps you ensure that all necessary precautions are taken to protect workers’ hands from injuries caused by tools, machinery, or hazardous materials. It includes key features like PPE inspection, hazard identification, and task-specific risk assessments. You can also customize it to focus on particular tasks, such as handling chemicals or operating heavy equipment, ensuring it aligns with your team’s daily activities and safety protocols.Hand tools safety checklist

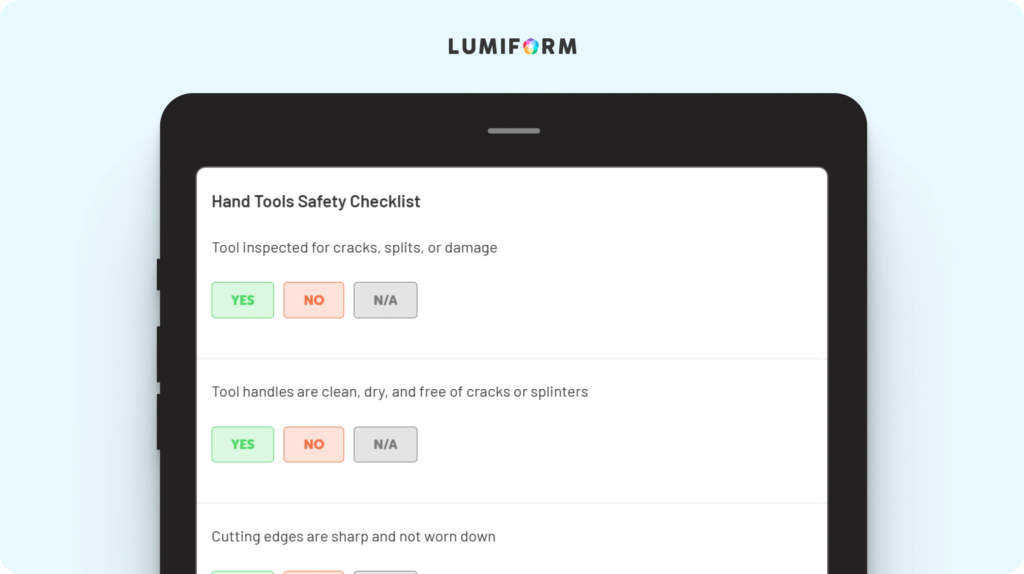

Designed to promote safe usage of hand tools, this checklist covers essential tasks like inspecting tools for wear and damage, while ensuring proper storage, and verifying training compliance. It simplifies the process of identifying risks and maintaining tool safety standards. You can adapt it by adding specific tools or inspection criteria relevant to your operations, making it an effective resource for preventing accidents and ensuring efficiency.Hand and power tool safety checklist

This checklist combines safety protocols for both hand and power tools, guiding you through tasks like checking cords and connections, inspecting tool guards, and verifying proper use procedures. It’s ideal for teams managing diverse tools in dynamic environments. Also, make sure you customize it by including specific power tools or adding maintenance schedules to ensure thorough inspections and consistent safety practices.Hand pallet truck safety inspection checklist

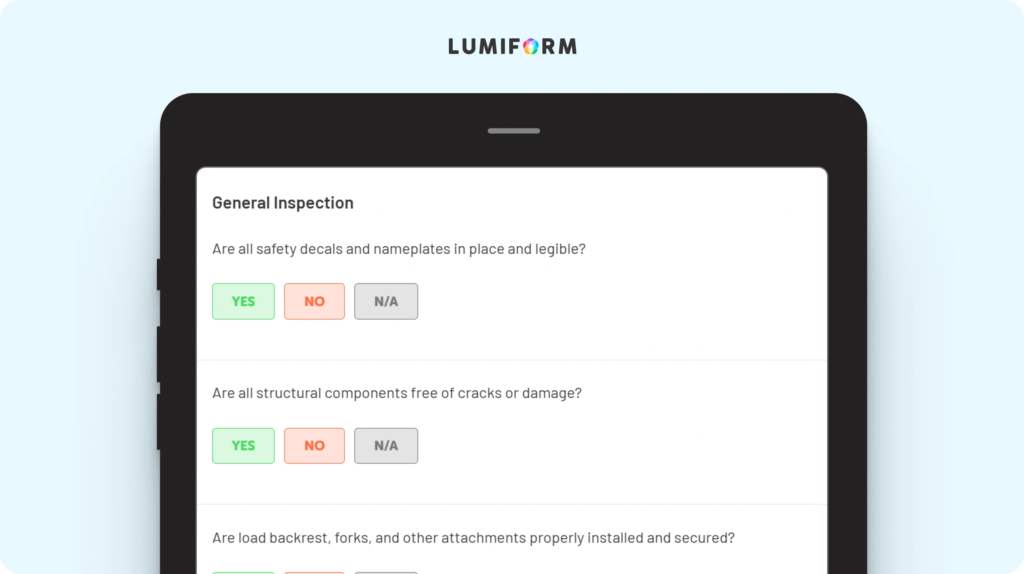

This checklist ensures the safe operation of hand pallet trucks by covering tasks such as inspecting wheels, brakes, and hydraulic systems, as well as verifying load limits. It helps you maintain equipment reliability and reduce workplace risks. Tailor the checklist to include your specific truck models or operational requirements, ensuring it fits seamlessly into your maintenance routine and keeps your equipment in top condition.

How to create a hand safety checklist in Lumiform

Creating a hand safety checklist in Lumiform is straightforward and ensures your team can follow consistent safety protocols to prevent injuries. Start by using the drag-and-drop form builder to include essential fields like multiple-choice questions for hazard identification, dropdown menus for PPE selection, and also photo uploads to document unsafe conditions.

To make the checklist easy for your team to use, add logic-based questions that adapt based on responses. For example, if a hazard is identified, the checklist can automatically prompt follow-up actions, such as scheduling glove replacement or additional training. This ensures no critical steps are missed while keeping the process efficient.

Assign roles to team members to ensure accountability, and use QR codes to link the checklist directly to workstations or specific tools, saving time and improving accessibility. After inspections, Lumiform’s analytics tools allow you to track trends and identify recurring issues, while helping you take proactive steps to improve safety.

By customizing the checklist to your specific tasks and risks, you can create a tool that ensures consistent safety practices and also reduces the likelihood of hand-related injuries.