When it comes to workplace safety, it’s essential to identify hazards even before they can become incidents. Whether you’re in construction, logistics, or any other industry, an effective hazard identification form helps you spot risks early, take action, and keep your team protected.

The templates below streamline the process for you, leading to clearer communication among your team as you maintain compliance with safety regulations. They’re also completely editable for your organization so you can start improving your safety processes today.

Top hazard identification forms

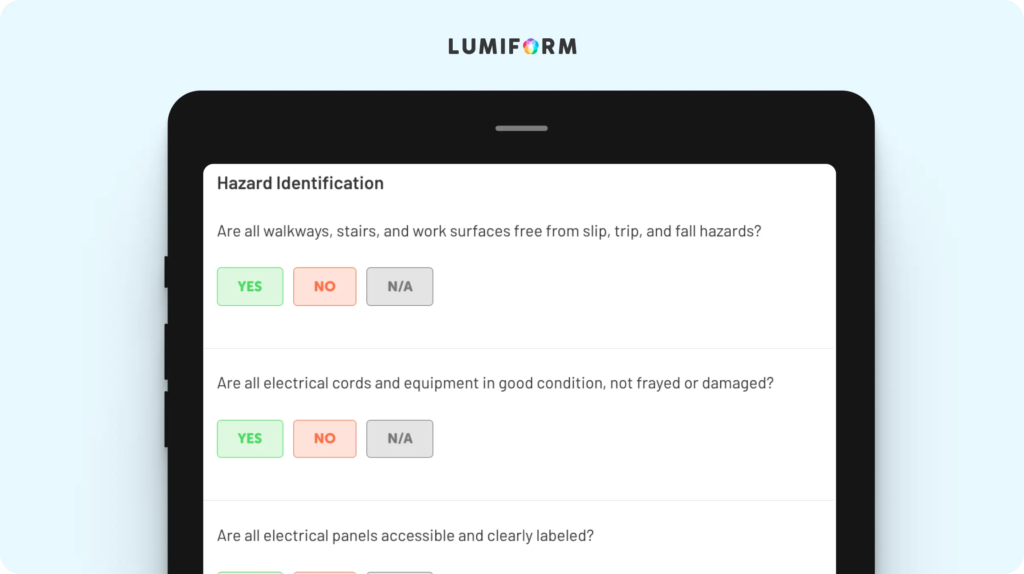

You can use these templates as interactive online forms with Lumiform’s dynamic features—like automated workflows and real-time reporting—or as downloadable PDFs:

Hazard identification checklist

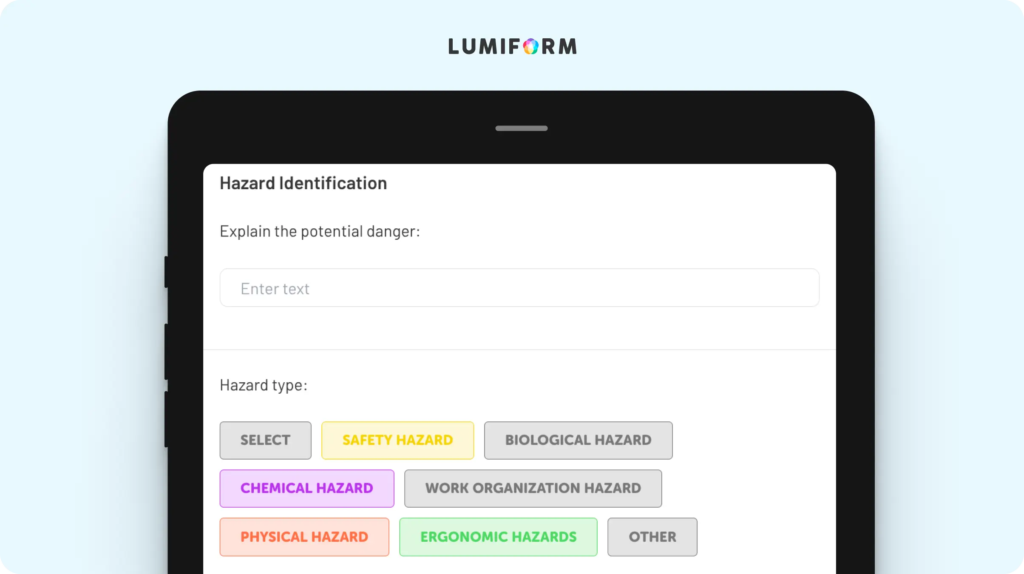

When managing safety on-site, you need a system to catch risks before they escalate. This checklist helps you systematically identify potential hazards, from tripping risks to equipment malfunctions. Key features include prompts for environmental, mechanical, and operational risks. To make it work for you, adjust the categories to match the specifics of your industry or work environment. Consistency is built into the template, making hazard tracking and communication across teams convenient.Hazard identification and risk assessment template

A tool that combines hazard detection with detailed risk evaluation, this template is designed for thorough safety assessments. You can document each hazard, rank its severity, and outline mitigation strategies all in one place. It’s particularly useful for complex workflows where prioritization is key. Tailor it by adding sections for department-specific hazards or unique project needs, ensuring every risk is accounted for.Noise hazard identification checklist

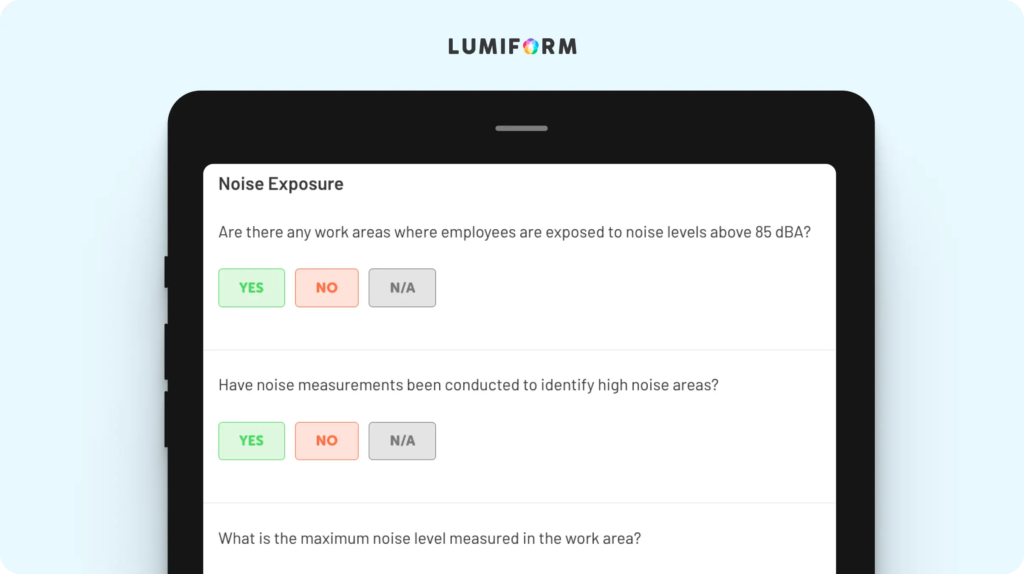

For workplaces with high decibel levels, like factories or construction sites, this checklist helps pinpoint noise-related risks. It includes sections for identifying noise sources, measuring exposure levels, and determining control methods. To adapt it to your needs, you can include equipment-specific checks or industry-specific noise thresholds. This structured approach ensures your team stays compliant with regulations while safeguarding hearing health.Forklift hazard identification checklist

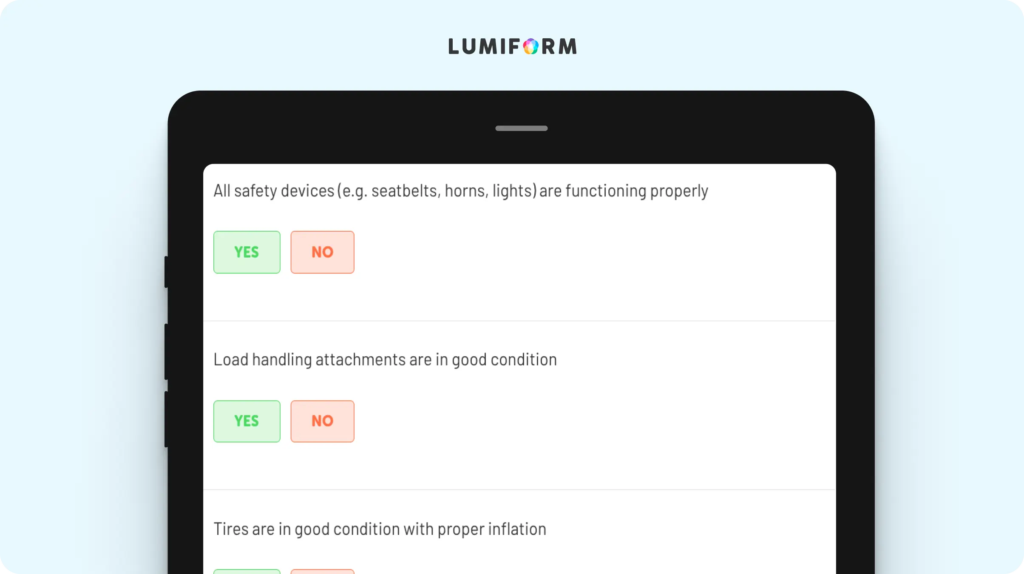

Forklifts can pose significant risks without proper oversight. This checklist focuses on identifying forklift-related hazards, such as blind spots, uneven terrain, or maintenance issues. Designed with busy warehouses in mind, it features prompts related to vehicle inspections, operator checks, and surrounding environment reviews. You can tweak it to include your facility’s unique traffic patterns or specific forklift models, making it a powerful tool for accident prevention.Workplace hazard identification checklist

From office spaces to industrial facilities, this template covers a wide range of workplace hazards. It helps you track everything from ergonomic issues to fire risks, ensuring a holistic view of safety. The flexible format allows you to customize sections to prioritize the most relevant risks in your environment. By focusing on proactive identification and consistent follow-up, this checklist supports a culture of safety and accountability.

How to create a hazard identification form in Lumiform

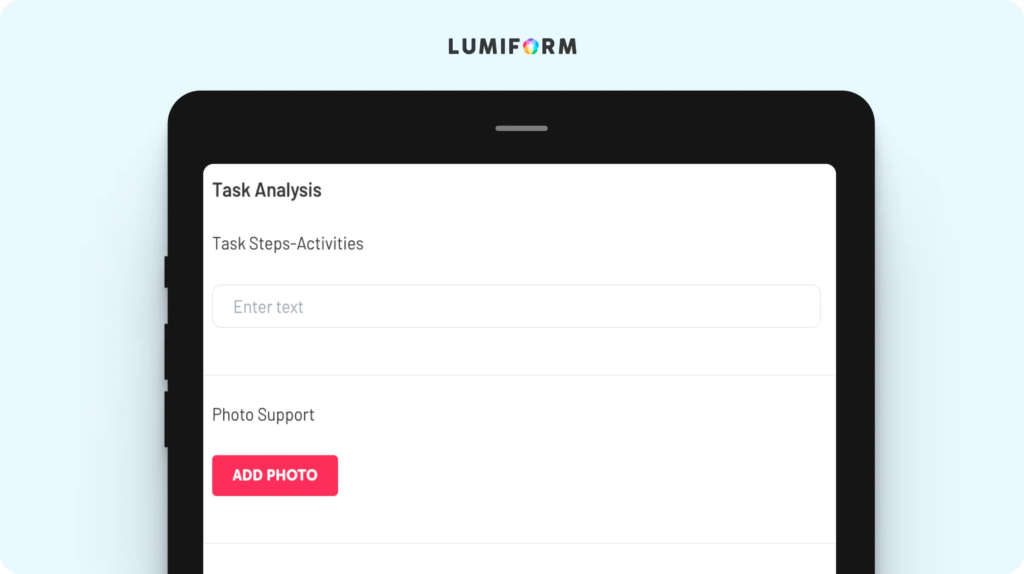

You can start by choosing one of the customizable templates above or create your own, with AI assistance—it’s entirely up to you. Using Lumiform’s drag-and-drop form builder, you can design a hazard identification form in minutes that fits your team’s exact needs. Include multiple input types, such as text fields for descriptions or photo uploads to capture on-the-ground details, ensuring every hazard is documented clearly and efficiently.

With the Lumiform mobile app, your team can access and fill out the form on-site, even without internet access. Hazards can be flagged instantly, and you can assign tasks for follow-up actions, so your team resolves issues quickly and consistently.

Once assessments are complete, Lumiform’s data analysis tools make it easy to generate reports, providing actionable insights to refine processes and prevent future risks.