Regular transformer maintenance is essential to ensure uninterrupted power supply and prevent unexpected failures. A transformer maintenance checklist helps you stay on top of key tasks like inspecting oil levels, cleaning bushings, and testing insulation. By following a clear and structured process, you can detect early signs of wear or damage, minimizing costly repairs and downtime.

Transformers are complex systems, and missing even small maintenance steps can lead to inefficiencies, overheating, or safety hazards. This checklist also ensures that every inspection is thorough and consistent, helping you maintain compliance with safety standards and extend the lifespan of your equipment.

With a reliable checklist, you can simplify maintenance routines, document findings effectively, and ensure your team works efficiently.

Transformer maintenance checklists

Keep your transformers running smoothly and safely with these comprehensive maintenance checklists, tailored to support regular inspections and proactive upkeep:

Transformer maintenance checklist

This checklist provides a comprehensive framework for inspecting and maintaining transformers, ensuring they operate efficiently and reliably. It includes key tasks such as checking insulation, testing winding resistance, and inspecting cooling systems to prevent failures and extend equipment lifespan. You can customize it to match your specific maintenance schedule or add inspection points for unique components, ensuring a tailored approach that addresses your facility’s needs.Oil type transformer maintenance checklist

Designed specifically for oil-filled transformers, this checklist focuses on tasks like oil level checks, dielectric testing, and identifying leaks. These features help you monitor oil quality and detect early signs of degradation, reducing the risk of overheating or equipment failure. Tailor the checklist by including additional tests or maintenance intervals based on your transformer’s operating conditions, ensuring consistent performance and safety.Dry type transformer maintenance checklist

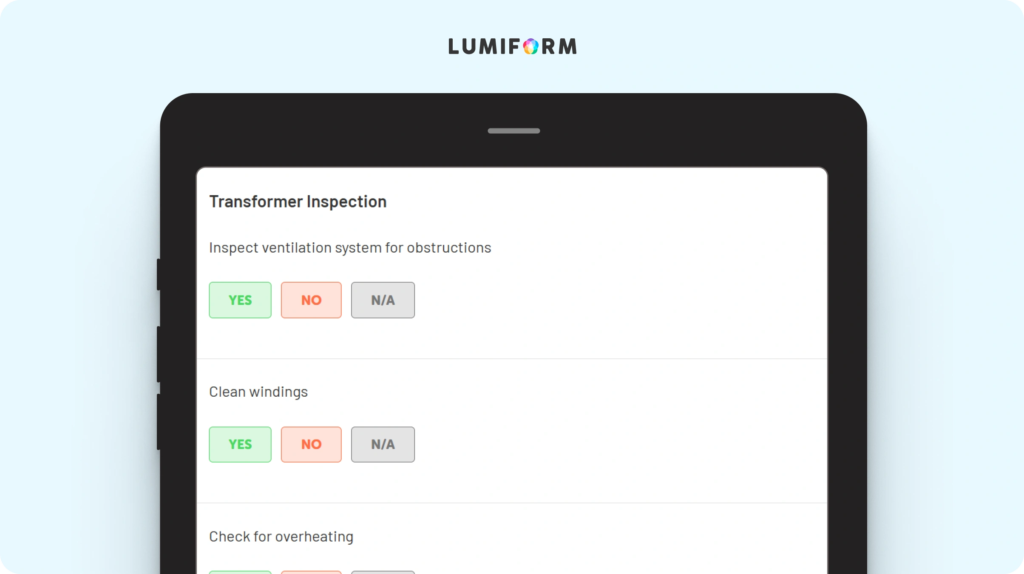

This checklist simplifies the maintenance of dry type transformers by guiding you through essential tasks such as inspecting ventilation systems, cleaning windings, and checking for overheating. It’s designed to help you maintain efficiency and prevent dust accumulation or thermal issues. You can adapt the checklist to include specific environmental factors or additional inspection items to suit your facility’s requirements.Transformer safety checklist

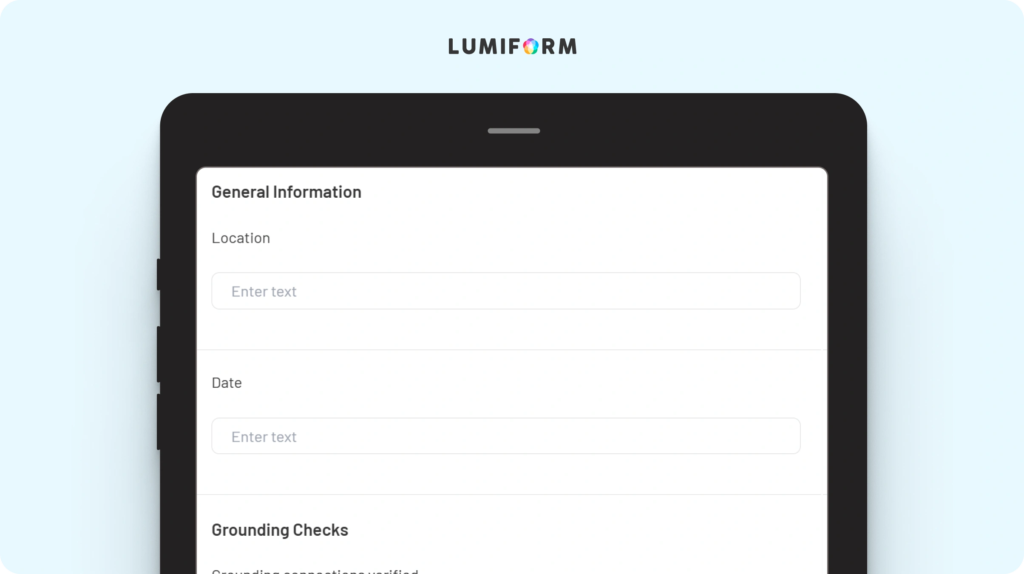

This checklist ensures the safe operation of transformers by focusing on critical safety measures, such as verifying grounding connections, inspecting protective devices, and reviewing emergency protocols. It helps you identify and mitigate potential hazards, ensuring compliance with safety standards. Customize it by adding location-specific risks or additional safety checks, creating a robust tool to enhance workplace safety and minimize risks.

How to create a transformer maintenance checklist in Lumiform

Creating a transformer maintenance checklist in Lumiform is quick and ensures your team can carry out inspections with consistency and ease. Start by using the intuitive form builder to include essential fields like dropdown menus for equipment types, number fields for recording voltage levels, and also photo uploads to document visual inspections.

To make the checklist even more user-friendly, incorporate logic-based questions that adapt based on responses. For instance, if an issue like overheating is detected, the checklist can automatically prompt follow-up steps, such as scheduling a thermal imaging test. This approach ensures thorough inspections without overloading your team with unnecessary tasks.

You can also assign specific sections of the checklist to team members, ensuring accountability and a streamlined workflow. Adding QR codes to your transformers allows your team to access the checklist directly on-site, saving time and reducing errors.

Once inspections are over, Lumiform’s analytics tools help you track trends and address recurring issues, enabling you to take proactive measures to maintain system reliability.

By tailoring the checklist to your needs, you can ensure consistent maintenance routines and improve the overall performance and safety of your transformers.